As the 3D printing frontier continues to expand with ever-increasing applications across virtually all industries, the need for and development of applications also continues to expand in the dental industry. Indeed, the world of dental education is no exception. Let’s take a few minutes to explore how professors at three universities have embraced 3D printing to illustrate this!

Development of the idea

As I was teaching occlusion and functional tooth anatomy over several years, I realized the importance of using the dental articulator to develop proper contours and guidance to emphasize what was being taught in lectures. However, we were using typodonts and unscrewing the plastic teeth to replace with prepared teeth for waxing purposes. Although the students were able to develop good waxing contours, the typodonts did not offer realistic functional movements like an articulator. Furthermore, the typodonts themselves were not able to be mounted onto an articulator.

I approached Whip Mix with an idea to scan the typodont and the prepared teeth and create a 3D printed model which could be mounted onto the Denar Mark 320 articulator that we use for education. My idea was to allow removable dies to be exchanged with ease without the need to screw and unscrew like the typodont. Furthermore, I requested different color “exam” teeth for the purpose of graded examinations of full contour waxing procedures.

The OSU Model

The Whip Mix engineers and production team were very efficient at making this project come to life, and as a result, the OSU Model was born. It had everything that I requested. These 3D printed models offer the following advantages in dental education:

- A clean, precise and exact replica of the typodont, which we were using with removable dies of prepared teeth for the purpose of full contour waxing.

- The printed models had multiple undercut recesses at the base which would allow for secure stone mounting onto the articulator and hence offer functional anatomical waxing.

- This process allowed us to teach mounting procedures with ease. The students were able to produce beautiful mountings using these printed models.

- There is extreme consistency with negligible discrepancies between the students’ models.

- All pre-clinical lab assignments can be completed on the same articulator, including custom guide table fabrication.

- They offer flexibility of design and the ability to modify.

- Different color options are available.

- Ability to store files for future print runs.

ACP Presentation

I was asked to give an oral presentation covering this new method of utilizing 3D printing technology for teaching occlusion during the ACP Predoctoral Educational Meeting in April 2017. Click here to download a few slides and pictures about this process.

At the University of Buffalo, Dr. Ramtin Sadid-Zadeh, DDS, MS uses 3D printing to teach students.

- One set of printed models with prepared teeth numbers 9, 18, 20 and 30 are used as follows:

- Students scan prepared teeth #9 and #30, after which they design crowns and mill lithium disilicate crowns. As a result, students learn how to modify the esthetics of anterior teeth using the printed model. They then stain, glaze and cement the crowns on the model.

- A PMMA fixed dental prosthesis (FDP) is milled for tooth numbers 18-20. The PMMA FDP represents a definitive FDP. Students section the FDP and record the pick-up impression to represent a pick-up impression in the clinical scenario.

- The University of Buffalo also uses printed models of actual patients to teach students how to develop a treatment plan for fixed prosthodontics. In addition to the printed models, students are provided with the radiographs, odontogram, medical/dental history and the chief complaint of the patient.

- Students then need to develop a comprehensive treatment plan for the patient, present the scenario, and most importantly, defend their decision.

Student Benefits at the University of Buffalo

“The use of printed models provides the opportunity for students to envision how they will manage the patient in the clinic. Specifically, the use of printed models for treatment planning purposes prepares students for comprehensive treatment planning exercises. The printed models provide the opportunity for thinking and planning comprehensively.” Dr. Ramtin Sadid-Zadeh, DDS, MS

At the University of Louisville, 3D printing is used to teach students

Occlusal splints don’t have to be complicated!

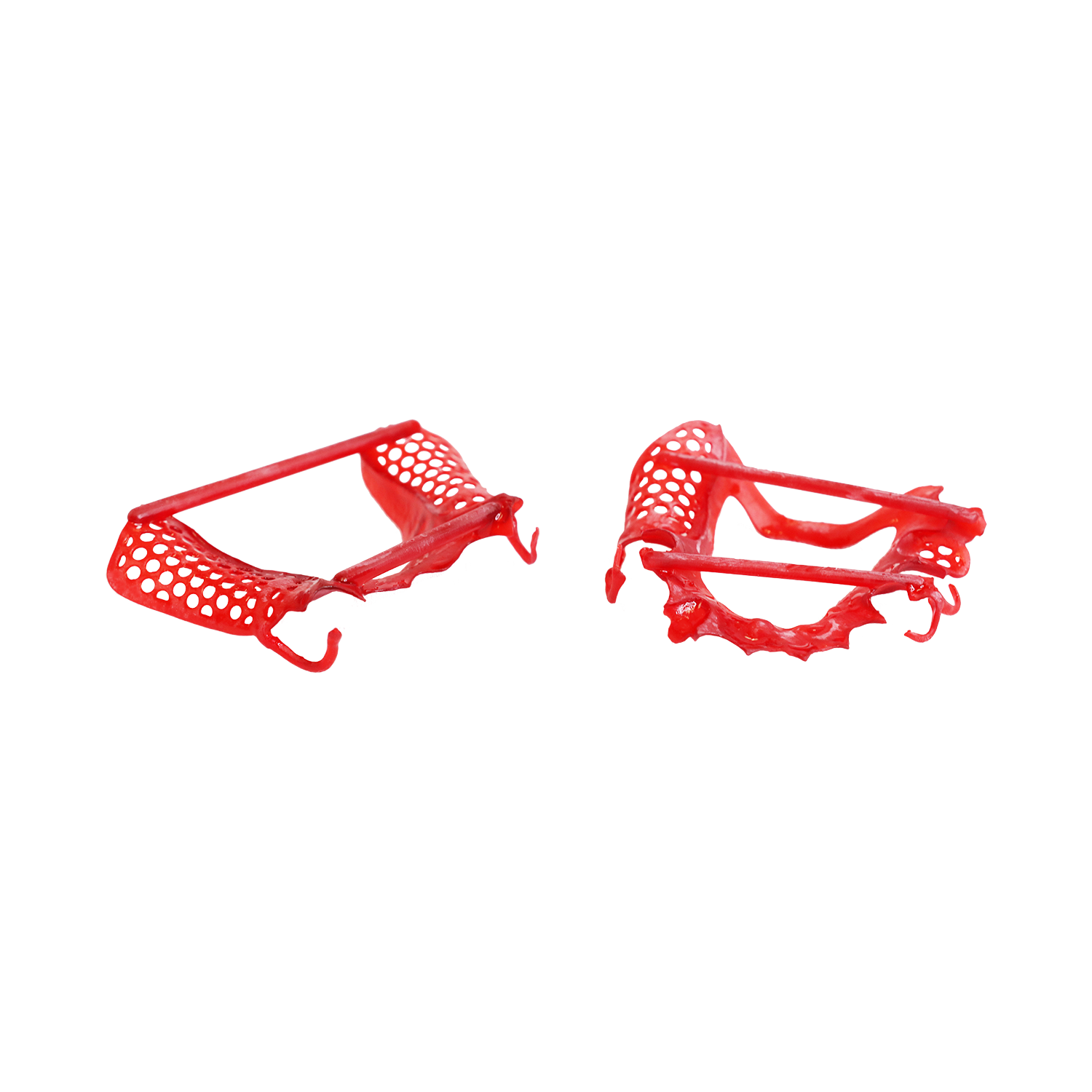

Click here to watch how Dr. Maddy provides his students with a hands-on experience demonstrating how to deliver a digital printed splint on models. Dr. Maddy shows us how he incorporates the delivery of a splint on epoxy models and a digital printed splint for his D2 occlusion course. A splint was made by a conventional laboratory technique on a set of epoxy mounted models. It was then digitally scanned, rendered into a software program and printed by Whip Mix. This project has all identical models and splints for consistency through this project.

Student Benefits at the University of Louisville

This exercise provides students with an experience that they can transfer to their patients in the future. Students will gain the knowledge that is required to deliver a custom printed digital splint with the understanding of the importance of utilizing an articulator to provide functional occlusion. The students will gain an understanding of the advantages of digital appliances.

As evidenced above, 3D printing will continue to advance educational environments at dental schools across our country. Contact your Whip Mix representative to discuss how we can help you!

.jpg)

Leave a comment