With Lab Day Chicago 2016 coming to an end, my colleagues and I noticed the newest trend taking over in the dental lab industry, 3D Printing. With 3D printing being a rather new technology there is still a lot of education needed on what 3D printing is, the types of printing available and which is best suited for the dental industry.

What is 3D Printing?

3D Printing is a process of converting a three dimensional digital object into a three dimensional physical object. The digital object is divided into horizontal slices by the desired layer thickness and then created by laying down the sequential sliced layers of material until the complete object is formed. There are 3 main types of 3D printing: Extrusion, Granular/Powder based and Light Polymerization.

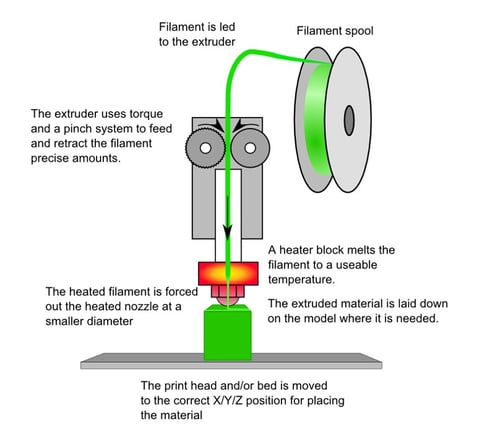

Extrusion 3D Printing

Fused Filament Fabrication (FFF)- is the process of building an object from the bottom up by heating and ejecting a thermoplastic filament layer by layer. This print style is most commonly viewed as the hobbyist's printer due to its simple form and low entry level cost. FFF can be used for creating prototypes, tools, toys, simple plastic jewelry, etc. Unfortunately, this style of printer does not print in a high enough accuracy and resolution for the dental industry.

Photo Credit: http://reprap.org/wiki/Fused_filament_fabrication

Photo Credit: http://reprap.org/wiki/Fused_filament_fabrication

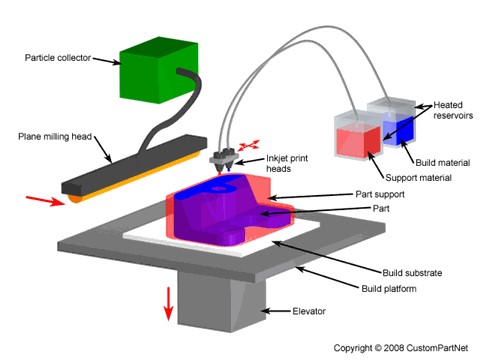

Inkjet 3d Printing- Inkjet 3D printing is also known as PolyJet Printing, MemJet, and MultiJet Printing. This process comes from the technique of inkjet printing, but instead of printing ink the head will extrude the material to be printed. The main advantage with this 3D print style is that more than one material can be printed at a time, usually consisting of a support like material and a main material that will form the object. This style of printing is already being used within the dental industry for creating dental models and castable dental restorations. The disadvantages with inkjet printing are: wasted expenses due to the mandatory support material, difficult post processing, slower print time, and high initial purchase price.

Photo Credit: http://www.custompartnet.com/wu/inl-jet-printing

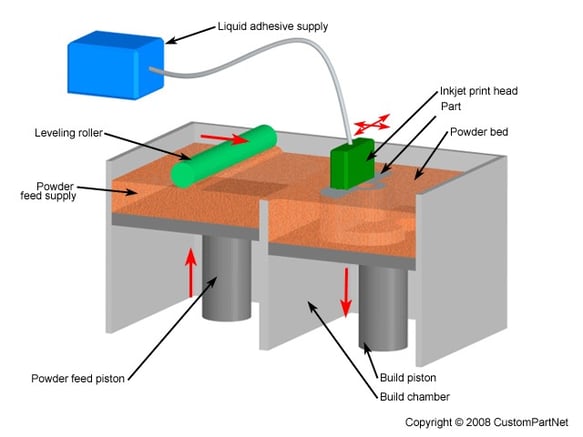

Granular/ Powder Based 3D Printing

BinderJet- is the process of taking a powder base material and using a liquid binder to solidify the object layer by layer. This process can also infuse color into the liquid binder to provide a multicolored object. However, Binderjet printing produces a lower resolution print, which is not ideal for dental restorations, but it is ideal for creating scale prototypes and medical models.

Photo Credit: http://custompartnet.com/wu/3d-printing

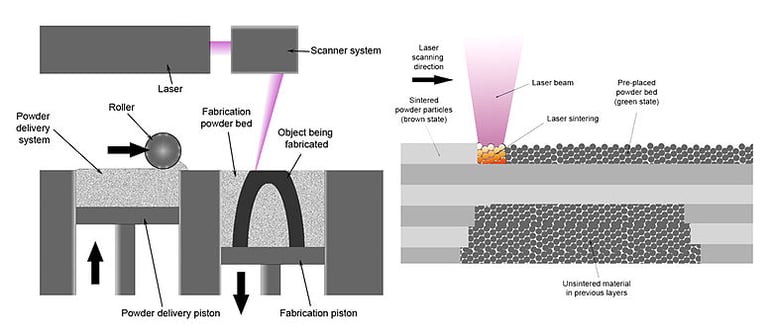

Selective Laser Sintering (SLS)- This process is quite similar to BinderJet in the idea of using multiple layers of powder to create the object. However, the difference being Selective Laser Sintering uses a laser to sinter and bind the material. The materials used in this type of printing can range between plastics, glass, to all types of metal. SLS is currently being used in a wide range of industries from medical, automotive, aerospace and the dental industry. Within the dental industry, SLS is being used for RPD frameworks, bridge frameworks, single copings, and even full contour restorations.

Photo Credit: https://en.wikipedia.org/wiki/selective_laser_sintering

Light Polymerization 3D Printing

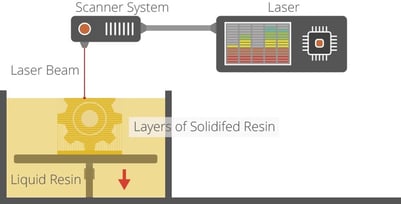

Stereolithography (SLA)- is the process of turning a photopolymer liquid resin into a solid object. SLA is actually the first form of 3D printing invented and it still widely used today. Within an SLA printer you will find 3 key components: a build plate, a resin tray, and a laser. During the build process the build plate will lower into the resin tray, where the liquid resin is placed, at this time the laser turns on and will draw/cure all the aspects of that current layer. After the current layer is completed, the ebuild plate will move away from the laser the exact distance of 1-layer thickness and then the next layer will begin to be cured. SLA is a great and accurate way to 3D print any objects and it can be used in all industries due to the wide range of materials that can be used. Unfortunately, SLA printing is not a fast method for 3D Printing in a production setting.

Photo Credit http://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/processes/

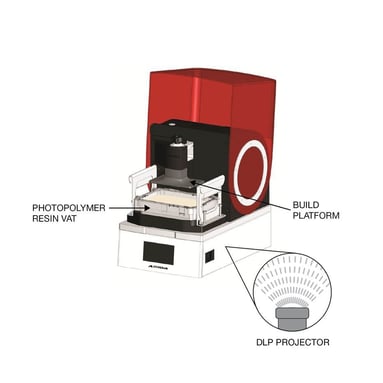

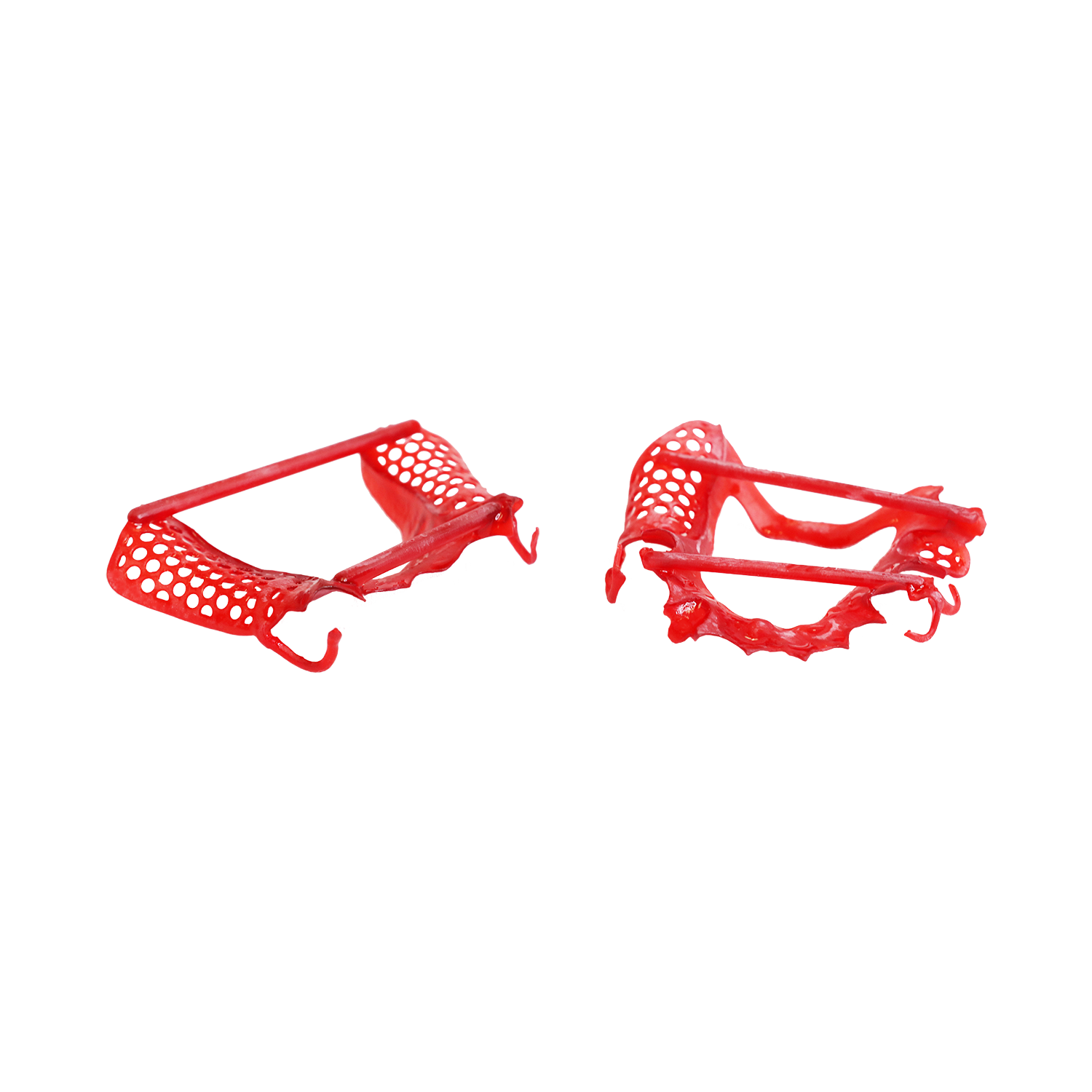

Digital Light Processing (DLP)- DLP 3D printing is a new form of SLA printing, in which the process and theory is almost identical, but Instead of a using a laser to cure the photopolymer resin, this form uses a DLP projector. This projector technology gives DLP 3D printing a huge advantage over standard SLA, as DLP 3D printing can print and cure a single layer across the total build plate in just a couple seconds, making it significantly faster. Another advantage that DLP has over SLA, and most other forms of 3d printing, is that it wastes very little material, which helps keep the cost per print to bare minimum. DLP printing is currently being utilized in the dental industry for creating Models from digital impressions, castable restorations, surgical guides, splints, and even short-term temporaries. Due to the speed and accuracy of DLP printing, this form of 3D printing will only continue to grow within dentistry.

Resources:

http://reprap.org/mediawiki/images/2/22/FFF.png

https://kylestetzrp.wordpress.com/2009/05/20/inkjet-and-multijet-printing/

http://3dprinting.com/what-is-3d-printing/#whatitis

https://en.wikipedia.org/wiki/Selective_laser_sintering#/media/File:Selective_laser_melting_system_schematic.jpg

http://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/processes/

.jpg)

Leave a comment