New, more affordable 3D printers are hitting the market everyday. As a result, a large number of dental labs have either already purchased one or are considering doing so in the very near future. If you are one of those labs, there are several important things to consider which will help you to determine if adding a 3D printer is right for you. Here are 4 things to consider before purchasing a 3D printer:

Needs Analysis

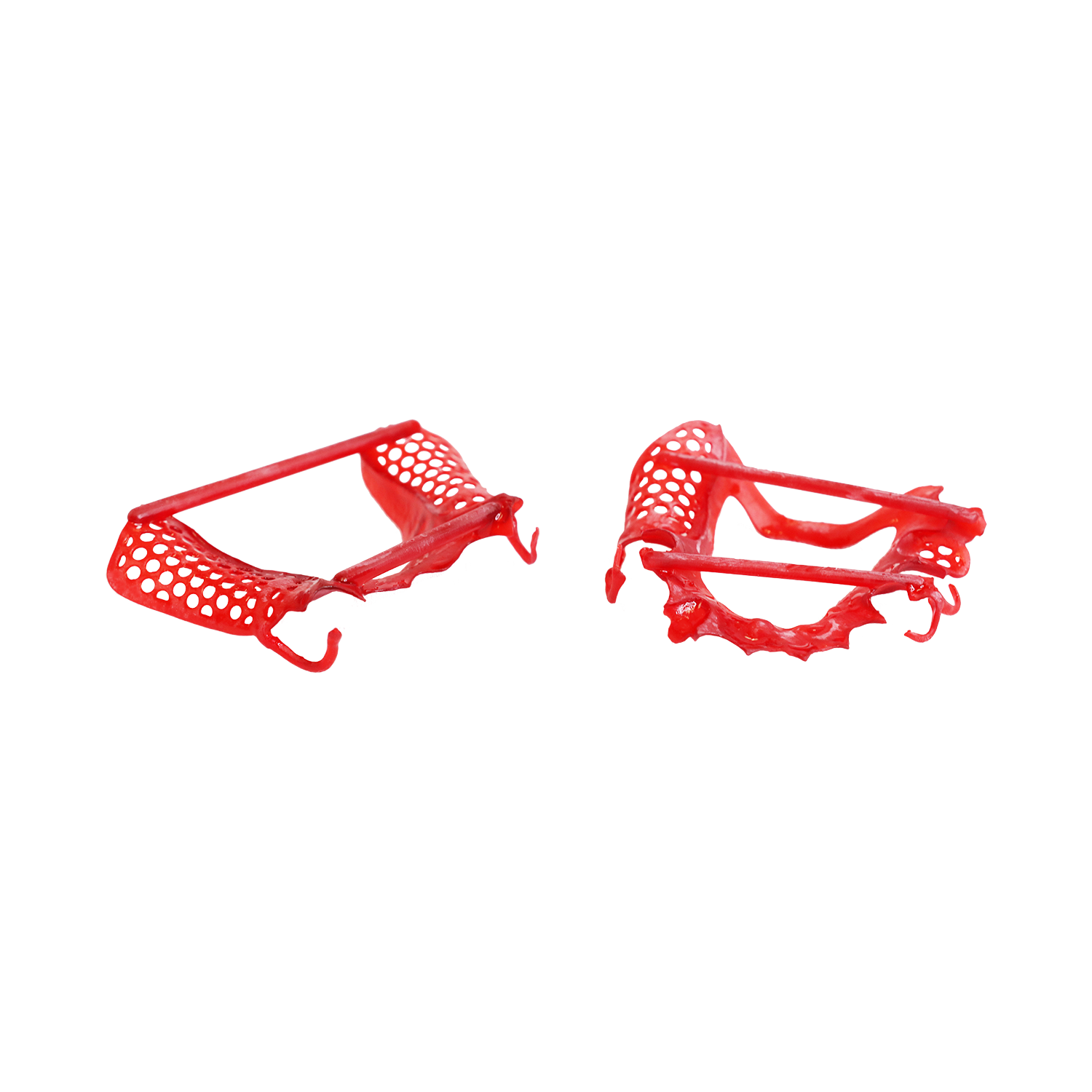

- What do you need the technology for? Are you starting to receive digital impressions and need to print models? Would the printer open a new line of business for you? For example, would you like to start offering surgical guides? splints? nightguards/bite guards, etc. printed from intaoral scans provided by your more progressive accounts?

- Would a printer improve a product or service you currently offer?

Printer Capabilities

- Can this printer be multi-purposed (can I use it to print multiple materials)? If it does print multiple materials, does it need to be purged between printing different materials? What is that process like?

- Is it an open material source printer? Am I able to use other manufacturer's resins or am I limited to using only materials from the company I bought the printer from?

- What is the changeover time when going from one resin to another? Something that is extremely important is the cycle time of the technology. If you are printing models, how long is it going to take to run a print job?

- How is the quality of the printed parts? There is one sure way to prove the quality of the printer. Before buying it, send a case (STL file) and let the company print a benchmark model for you to prove out the technology. You can even send the file to multiple companies and compare their results.

Integration Analysis

- Space - Do you have enough room for the printer and related equipment and materials?

- I.T. - Do you have someone to support and maintain the software/hardware?

- Integration - Will it integrate with your current CAD system?

Operator considerations

- Training - Will the company you purchased the printer from be able to provide comprehensive training to your technicians?

- Compentency - Who are the right people to train in your lab?

- Capacity - Will your lab be able to handle the added workflow and productivity?

Cost Analysis

- Purchase Price - What is best for you? Buy it outright or finance it?

- Annual maintenance contract - Is the cost justifiable?

- Material cost - How much does it cost to print a model, guide, pattern etc.?

- Other consumables - What other consumables will you need to account for?

Obviously, there are a lot of things to consider when purchasing a 3D printer. Your printer re-seller or manufacturer should be able to answer all of these questions for you. As I have said many times, there is no such thing as a plug and play 3D printer. There are adjustments that need to be made to your 3Shape or ExoCAD software, adjustments that may need to be made to the material files, and adjustments to the printer itself. The key is to look at a printer like the Asiga, and to work with a company that can answer all of you questions at the beginning, and will also be there to support you long after the purchase.

.jpg)

Leave a comment