After a recent visit to the physician, I am reminded that we often overlook the internal parts of our machines. Weather that is our own bodies or the machines in our laboratories, we need to take care of both the outside and the inside.

After a recent visit to the physician, I am reminded that we often overlook the internal parts of our machines. Weather that is our own bodies or the machines in our laboratories, we need to take care of both the outside and the inside.

An office sent in a photo of a water supply line to one of the Whip Mix machines and requested a replacement for the ‘black water line’. That line is not black…it is clear.

If you have allowed the line to build that much bio-muck, then it certainly needs replacing. However, more than that, it needs better maintenance.

Most of the machines that Whip Mix manufactures have internal parts that are maintainable by the technician and should be addressed on a routine maintenance schedule. For example, we recommend that you use the Vac-u-Care Maintenance Kit (Item# 28398) for the Combination Unit and the Powermixer Plus vacuum mixing machines every five years. I know…you have had your mixer for 20 years and have never done anything and it works fine. I have seen a few of those and they are one-step away from disaster in most cases.

The internal parts of these machines would be the vanes in the vacuum pump, and the ‘O’ rings and felts in other areas. These are sometimes hidden and the old adage, “out of sight, out of mind”, often applies.

Some of the most overlooked internal parts are the ‘O’ rings on the paddle shaft of your vacuum mixing bowls. Yes, there actually are some! These should be replaced or lubricated on a regular basis to insure a good vacuum seal and correct positioning of the shaft against the bearing surface of the lid. To access them, remove the drive nut from the top of the shaft and pull the shaft from the lid exposing the ‘O’ rings. Check them for flat spots or other wear and tear and then, either replace or lubricate them with some Lubriplate (Item# 07420). Re-assemble the paddle shaft/Lid/Drive Nut assembly and mix some more.

Is the vacuum tube connection loose in the lid of the mixing bowl? When was the last time you replaced the ‘’O’ ring on the end of the trap cap? It does wear over time. How about the Foam Filter in the throat of the VPM2 mixer?

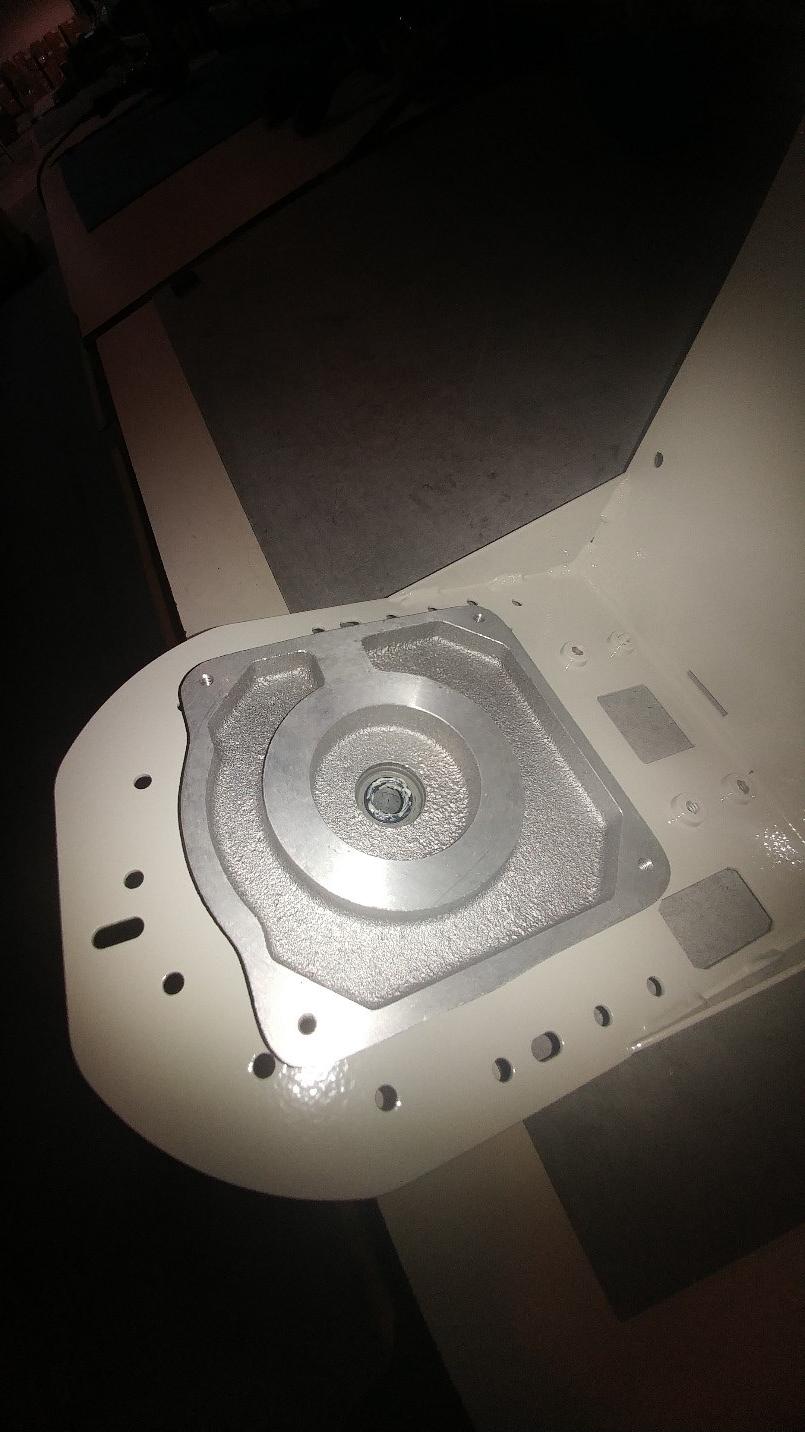

Your porcelain furnace has a gasket between the lift table and the wall of the muffle chamber. Is it getting old? Has it developed flat spots? Is it allowing some vacuum leak, which causes your vacuum to work overtime? Are the vacuum lines themselves getting older and more brittle? Is porcelain dust beginning to build up on internal boards and parts?

Are vacuum bags and filters replaced on a regular basis in your in-line and standalone vacuums?

Much like the filter on the furnace at home, these parts need regular and scheduled maintenance for the best performance. Setting up that schedule on your calendar or computer reminder will make these internal yet integral parts of your operation last longer and perform better.

If you have questions about any of these or other parts, please call us at Technical Support or visit our website at www.whipmix.com for answers or step-by-step video on how to accomplish these tasks.

Leave a comment