The most common type of wheel used on model trimmers is composed of carborundum or aluminum oxide. There are also peel and stick discs with 50 grit sandpaper. Whip Mix even offers super abrasive diamond wheels that offer aggressive cutting and years’ worth of service with proper care.

With the traditional carborundum wheels users often become frustrated that their cutting effectiveness can diminish over time. The busier the lab or dental office, the quicker this can happen. Usually the lack of cutting force is not due to wheel wear, but rather a buildup of stone on the wheel itself. Cleaning can be done in one of two ways.

First, you can spray the wheel with Simple Green and allow it to soak. This will loosen the stone buildup. Then scrub it with a stiff bristle plastic brush to remove the majority of the caked on stone. You should periodically rinse the wheel with clean water. You can also use Cleancut Wheel Cleaner Item # 09602. Remember to shut the water off during this process to get the best results. The Cleancut Wheel Cleaner resembles a long rectangular pencil eraser. You simply push against the running trimmer wheel while it lays flat on the work table assembly. Move it from side to side to hit all the areas of the wheel.

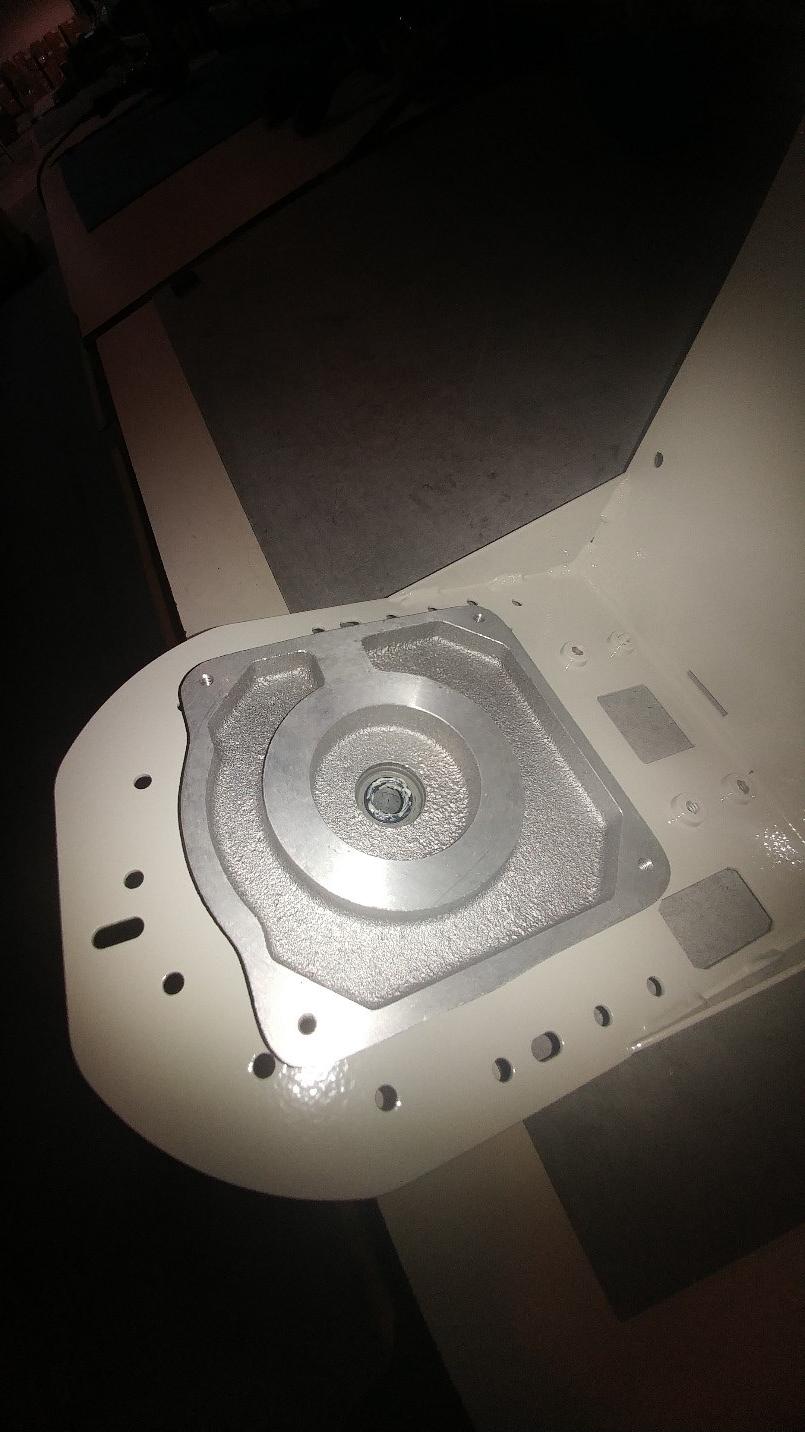

One other way to get extra life out of the wheel is to simply take the wheel off, flip it over to the other side and re-secure it. This should only be done if the wear on the wheel is relatively even. If the wear on the wheel shows a deep groove in just one area it is not advisable to flip the wheel and use the other side. This could make it to break during use.

Leave a comment