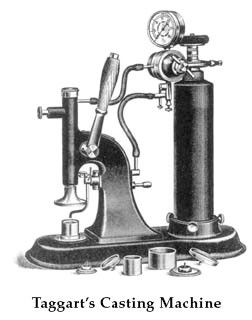

In 1907, a dozen years before Whip Mix was incorporated, Dr. William Taggart, a Chicago dentist, patented a process and casting machine to make gold inlays and crowns. Unfortunately, his innovations were so widely copied by others that he found it impractical to enforce his patents against practicing dentists who found similar but different ways to make castings for their patients. Dental casting investment powders were key to getting a well-fitting casting and they were packaged and sold in small cannisters of 5 pounds and fiber drums of 100 pounds. Dental plaster and stone were generally sold in the same sizes.

By the early 1950’s the dental literature was filled with scientific studies that explored the many influences that affected how a dental casting would fit back onto the patient’s prepped tooth. Indeed, Robert Neiman, an 8 year veteran at Whip Mix in 1944, presented a paper on the industrial lost wax casting process.

The water to powder ratio of the refractory investment was one of the major influences on the casting fit. Whip Mix had already developed and marketed a clever device, the Whip mix Proportioning Unit, which simplified the process of weighing the investment powder. This helped ensure that the refractory investment water/powder ratio was easily repeatable and accurate. But the weighing process still caused dust and the bulk investment powder could be adversely affected by exposure to humidity in the air should the container be poorly sealed.

The water to powder ratio of the refractory investment was one of the major influences on the casting fit. Whip Mix had already developed and marketed a clever device, the Whip mix Proportioning Unit, which simplified the process of weighing the investment powder. This helped ensure that the refractory investment water/powder ratio was easily repeatable and accurate. But the weighing process still caused dust and the bulk investment powder could be adversely affected by exposure to humidity in the air should the container be poorly sealed.

At the prodding of company management, particularly Harvey Sollinger, a project was initiated in the mid 1950’s to address these shortcomings.

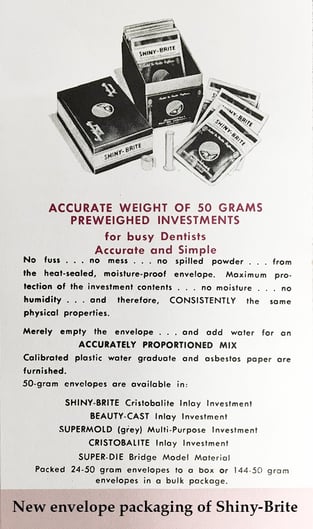

Harvey and the team settled on using new packaging and technology --- layered film with polyethylene sandwiched between layers of paper and aluminum foil. The resulting pouch could be formed at the film manufacturer/converter, filled at Whip Mix with the fresh investment powder and the open end then sealed with heat and pressure to create a moisture-proof envelope. Development of these envelopes was a learning process. Much trial and error was involved as well as the use of key film supplier, Mr. Joe Mosher, who committed his expertise and knowledge to help Harvey and the team optimize the film’s structure, package size and other factors while also holding down film costs, and other packaging expenses.

Though labor was needed for the filling, sealing and packaging process, Harvey recognized that customers would still prefer the more expensive packaging in view of the longer shelf life of the powder, the elimination of silica dust and the more consistent fits of the castings, i.e. – fewer casting remakes.

The “preweighed envelopes” were introduced to dentists and technicians in 1955. It is interesting that the final size offered was in the metric system (grams of powder) while the cartons were done in the British system of dozens…boxes of 24 and cartons of 144 envelopes.

By 1974, demand had grown to the point that the company needed 20 personnel to fill and seal the pouches, spread over 2 shifts in order to meet customer demand. This success spawned imitations by numerous competitors, yet the Whip Mix powder weight accuracy was (and still is) considered to be the yardstick by which others are measured. And, of course, the quality control of the powder and never-ending search for better raw materials also set the Whip Mix investments apart, especially with the 1961 introduction of Ceramigold phosphate bonded investment used for casting the high fusing gold alloys needed for baking porcelain onto the metal substrate (Porcelain Fused to Metal).

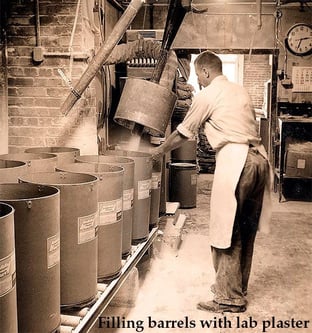

By the mid 60’s, our success with the preweighed envelopes of investments generated a desire to do the same style packaging for our gypsum die stones and model stones. Harvey eventually settled on working with the Hayssen Corporation, a company who had created a special machine that needed only 1 operator to form, fill and seal the envelopes. Once set up, it would produce a 50 gram envelope of dental stone every 3 seconds. Of course the devil was in the details - - it took a lot of experiments and custom modifications before the new system was able to reliably fill envelopes within the needed weight tolerance. We ended up using our machine shop to fabricate custom augers with special “spiders” cast in our quality control lab. We even came up with a way to reverse the augers and double their life. Paul Phillips and Bill Sebree were Whip Mix machinists with these great innovative ideas.

By the mid 60’s, our success with the preweighed envelopes of investments generated a desire to do the same style packaging for our gypsum die stones and model stones. Harvey eventually settled on working with the Hayssen Corporation, a company who had created a special machine that needed only 1 operator to form, fill and seal the envelopes. Once set up, it would produce a 50 gram envelope of dental stone every 3 seconds. Of course the devil was in the details - - it took a lot of experiments and custom modifications before the new system was able to reliably fill envelopes within the needed weight tolerance. We ended up using our machine shop to fabricate custom augers with special “spiders” cast in our quality control lab. We even came up with a way to reverse the augers and double their life. Paul Phillips and Bill Sebree were Whip Mix machinists with these great innovative ideas.

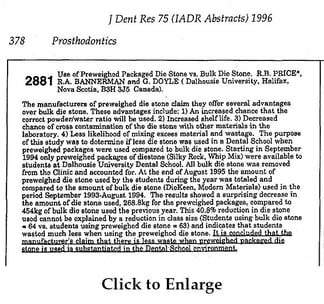

However, sales of preweighed gypsums were hampered by dental school administrators focusing on the higher cost per pound. The big breakthrough was an abstract published in 1996 following a test comparison at Dalhousie University in Halifax. The study concluded that there was less waste using the envelopes, so that the actual cost per cast poured was almost the same… and that preweighed gypsums had other advantages like less mess, no contamination issues and better cast quality. Needless to say, Dr Mike Mansfield, our schools rep at the time, made sure that his faculty connections at all 65 dental schools in North America received a copy of the article. Within a few years, dozens of the schools had adopted the use of these convenient pouches.

Today, Whip Mix envelopes are filled and sealed on equipment that is 4 generations more advanced from that original Hayssen machine. We now use these machines to package all our powder products - - - investments, stones and plasters into a variety of sizes from 50 grams to 2 kilograms. While we still offer most products in bulk packaging up to 11 kilos, the dental market has developed an affinity for unit dose preweighed envelopes. Dental students at most schools are using envelopes of Whip Mix gypsums and investments, which furthers their loyalty to the Whip Mix brand and packaging when they go into a private practice setting after graduation.

David Steinbock, Mike Leis, Alan Johanboeke, Brian Knopf and a host of other team members can take pride in the integral parts each has played in continually seeking out better packaging materials and machines. Today, we turn out well over a million pounds of powder a month with fewer than 30 team members in total involved in the formulating, blending, testing and packaging.

Which brings me to my oft-stated quote when I take our visitors on a tour, “We make it by the ton, but sell it by the gram.”

.png)

Leave a comment