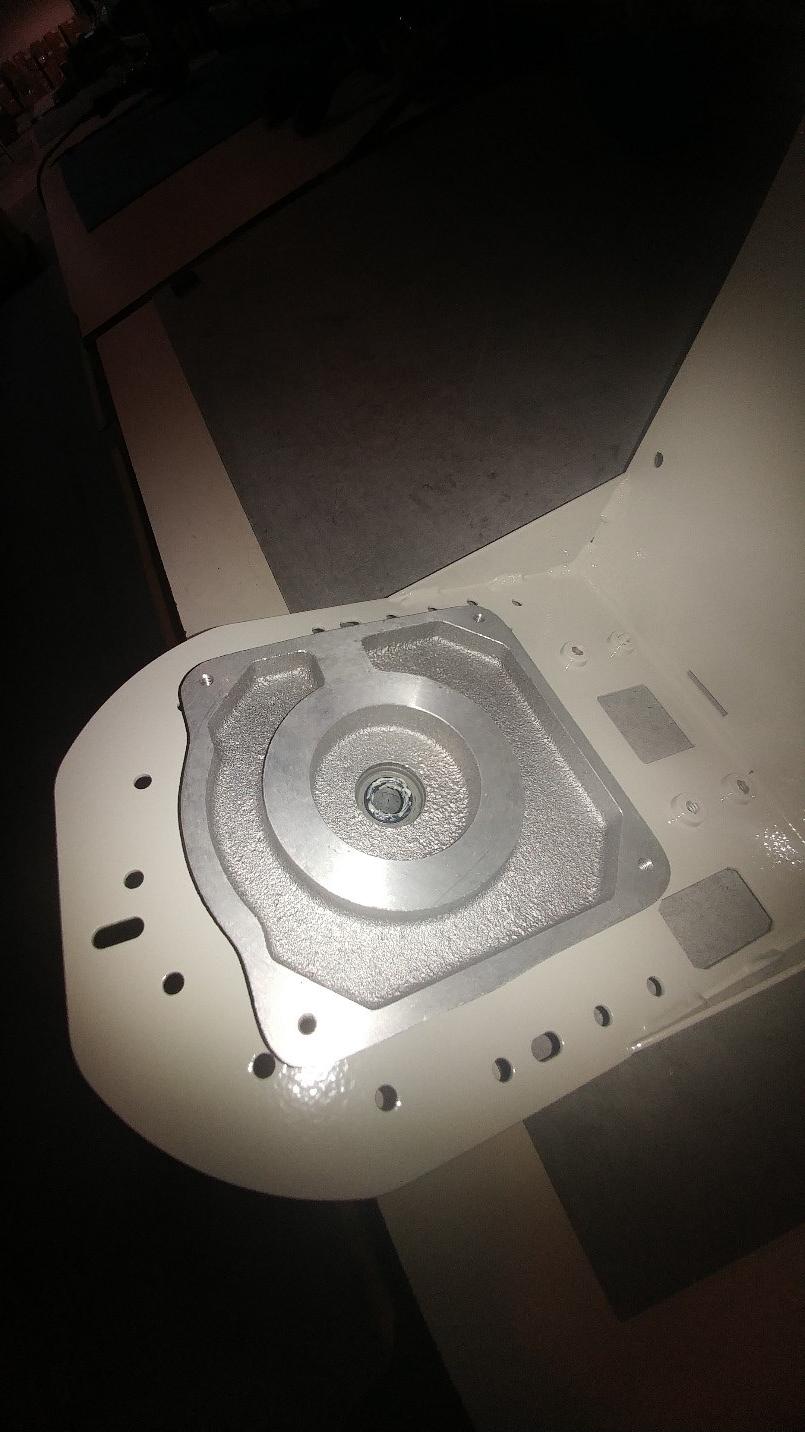

The model trimmer is the workhorse in the lab and clinical setting for establishing a well-formed cast, once the impressions are poured in the gypsum of choice. When the casts are recovered from the impression, you are ready to trim the model.

The model trimmer is the workhorse in the lab and clinical setting for establishing a well-formed cast, once the impressions are poured in the gypsum of choice. When the casts are recovered from the impression, you are ready to trim the model.

The first step in a Wet Model trimmer is to dampen the model. The resulting slurry created by the trimmer is sticky, and could find its way into occlusal grooves and other surfaces that might play havoc with function.

In some cases, only minimal trimming is required just to make a quick diagnostic model, but nothing really display worthy. Sometimes though, presentation quality is important and that is where certain trimming techniques can make a big difference in the visual aspect of the model.

The standard approach is to set the cast on the worktable and push strait into the grinding wheel. While this will remove stone and yield a relatively flat surface, it may not, however, come out as smooth as one would like. On occasion - with all grit sizes of grinding wheels - you will notice concentric circular lines. These lines might be viewed as a wheel defect, but this simply is not the case.

One way to minimize the lines on the surface of the cast/model is to move the cast back and forth, laterally on the worktable while the forward force is being applied to the model. This motion will remove stone, but also smooth the ground surface.

At the end of the process, a lighter touch typically will yield a smoother surface. Remember that these wheels are COURSE, not fine. If an ultra-fine surface is desired, 400-grit wet dry sandpaper under water, followed by 600-grit wet-dry sandpaper with water will soften and smooth the surface.

We need to keep in mind that the model trimmer’s function is to reduce and flatten the stone surface and is not the end of the process for a super fine surface.

Leave a comment