Technology in the dental industry is rapidly evolving. The newest wave is additive technology, also known as 3D printing. It has become increasingly popular in the dental industry due to the speed at which it creates multiple objects through sequential layering, its ability to produce fine detail and its accuracy.

Technology in the dental industry is rapidly evolving. The newest wave is additive technology, also known as 3D printing. It has become increasingly popular in the dental industry due to the speed at which it creates multiple objects through sequential layering, its ability to produce fine detail and its accuracy.

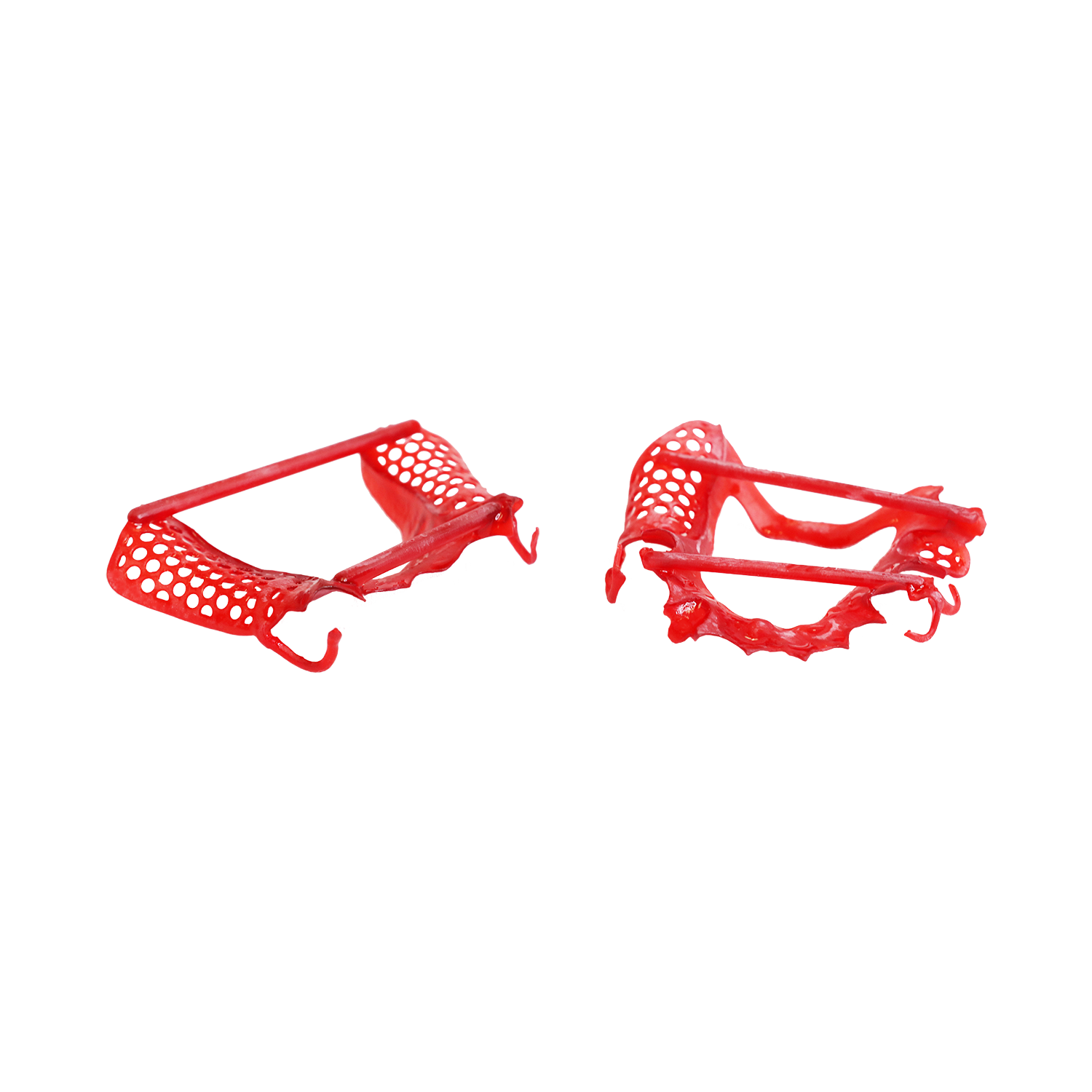

The ProJet 1200 3D Printer is able to produce 10 to 12 burnout patterns for pressing ceramics or casting alloys within approximately 1-hour of build time. Dental labs are able to cut the labor time of waxing each individual unit by hand. With CAD software, thin areas can be avoided, complex occlusal schemes can be easily replicated and bridge connectors are made to the proper size. The final product is not only dimensionally accurate, but detail rich.

With a price of $4,900 (plus material, service fees) what’s stopping your lab from saving time and money, increasing production and ensuring consistency?

.jpg)

Leave a comment