Older technicians will remember the introduction of solid plastic sprues back in the 80’s. What a great idea! There would not be as much heat retaining wax, and they would help eliminate distortion by introducing some rigidity to the sprued patterns. They did do all of that, but we also started noticing cracking in the investment and finning on the castings. We solved the issue by coating the sprues with wax before investing. This coating gave the sprues “room to move” as they burned out. Eventually hollow sprues replaced those solid ones and the problem was solved. What we never talked about was the cause of the problem. As long as the problem was fixed, we were happy.

Now nearly a generation later, companies introduced 3D printing of resins into our industry and we began facing the same issues all over again.Early adopters of printed copings were fine when the volume was low, but as the number of copings in the ring increased, or the size of the patterns became larger, we saw the same investment cracking and finning of the casting or pressings.

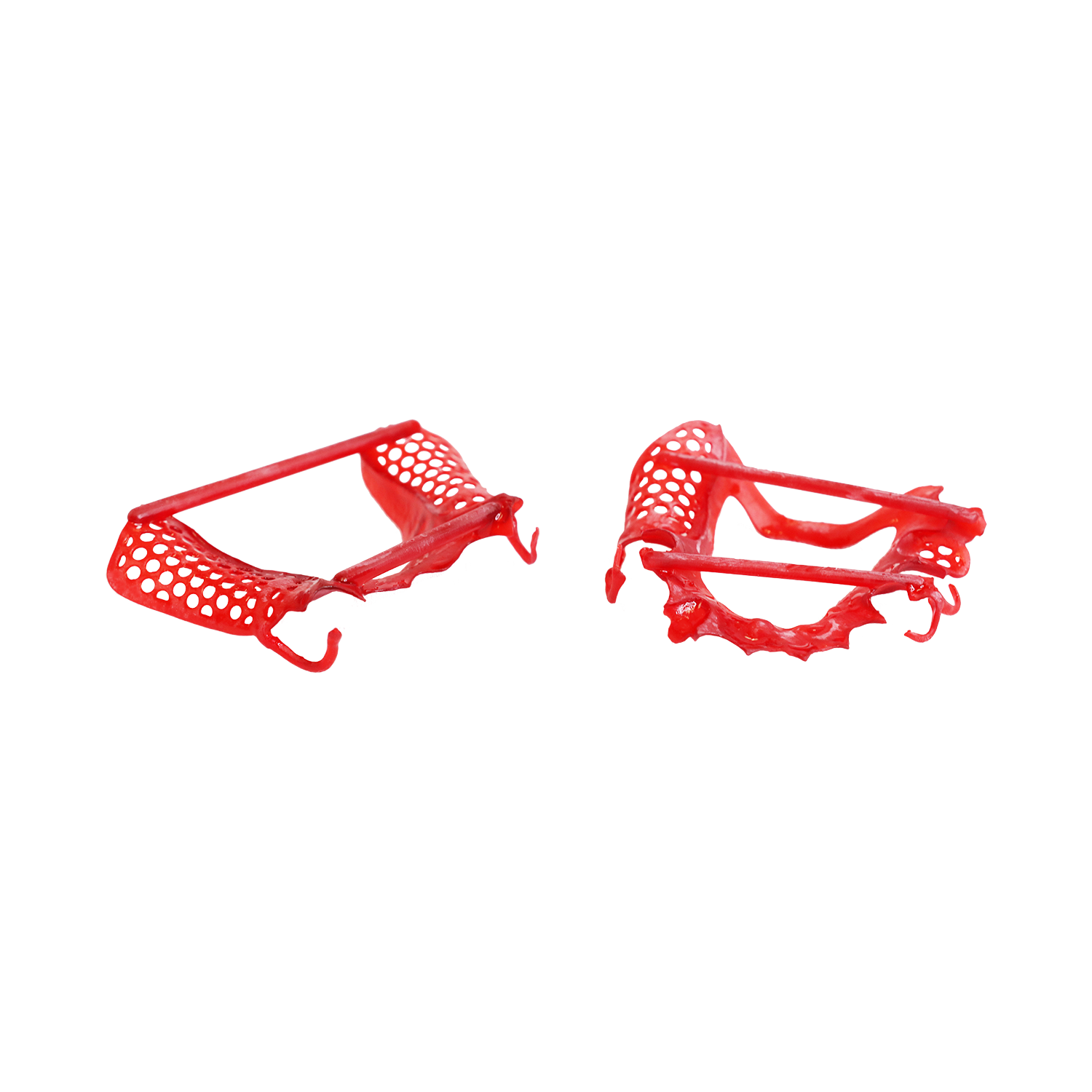

Now we have progressed to where we have the design and print capabilities for partial denture frames whose volumes of resin material create an even bigger challenge. Therefore, we need to talk about what is actually happening in the ring while the resin material burns out.

Unlike wax, which softens (and sometimes melts) when the phosphate investment reaches nearly 185°F during its initial bench set, resin does not behave this way. The temperature change from where resin begins to soften and where it volatizes (bursts into flame) is small. This rapid change from a solid into an ignited flammable gas causes tremendous pressure on the surrounding investment and can fracture the mold.

Jewelry companies, which were into 3D printing before dental, actually solved this issue by coating their patterns with a spray of clear acrylic paint, reminiscent of the dental techs of the 80’s and coating solid sprues with wax. However, because of our accuracy issues in dental, we are not able to approach the problem in this manner. Slow long burns or multiple stage burnouts do not solve the issue because the change happens so rapidly. We simply need a tougher investment, which is resistant to fracture.

Whip Mix developed ResinVest phosphate investment for that reason. It was created specifically for burning out printed resin RPD framework patterns and is fiber-reinforced to strengthen the investment's resistance to pressure cracking and finning.

In addition, this high performance investment offers a wide expansion range and optimal casting fit. It also features a rapid burnout technique in order to reduce processing time and increase productivity.

For more information on the ResinVest, contact us at 800-626-5651.

.jpg)

Leave a comment