The most common call I receive regarding the Xcavator is that the ring did not divest properly. There are several things that might cause this. Each has an easy fix.

1. First, is using Whip Mix glass beads and keeping them constantly warmed and dry by the heating belt around the bead bucket? The reason I ask if they are Whip Mix beads is because we have found that our supplier’s beads are more consistently spherical than others we have seen and that they are always 50 microns in size. Some competitor beads which are not consistent in shape and size tend to clog. Also, beads that aren’t constantly warmed with the bead belt can take on and hold moisture which will definitely clog the unit. Make note of the pressure on the pressure regulator it should be set at 35 psi (the regulator in fig. 1 is too low).

1. First, is using Whip Mix glass beads and keeping them constantly warmed and dry by the heating belt around the bead bucket? The reason I ask if they are Whip Mix beads is because we have found that our supplier’s beads are more consistently spherical than others we have seen and that they are always 50 microns in size. Some competitor beads which are not consistent in shape and size tend to clog. Also, beads that aren’t constantly warmed with the bead belt can take on and hold moisture which will definitely clog the unit. Make note of the pressure on the pressure regulator it should be set at 35 psi (the regulator in fig. 1 is too low).

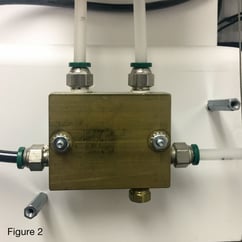

2. Another area that should be looked at is the reservoir and its lid. The gasket should be free of beads under and on top. In addition, make sure there are no beads in the threading of the lid or jar. These beads can prevent a good seal and cause cutting issues. At the base of the jar there are two 3” plastic tubes - one in the back which allows air in the jar and one in the front which allows the beads to fall into the brass block. The tube in the front can sometimes become frayed at the bottom from the constant flow of beads and the air blowing across the surface to move the beads out of the pen. This is normal, given the abrasive qualities of glass beads. Periodically, both of those tubes, especially the front, need to be replaced: (#09841 /5355 Air Hose 3 Inch Pkg. 2). Also, our department that repairs our dental laboratory equipment finds that the fittings that are on the brass block can wear over time, especially the top and front one leading to the pen: (# 09835 /5340 Male Connector ¼ Inch (see fig. 2).

2. Another area that should be looked at is the reservoir and its lid. The gasket should be free of beads under and on top. In addition, make sure there are no beads in the threading of the lid or jar. These beads can prevent a good seal and cause cutting issues. At the base of the jar there are two 3” plastic tubes - one in the back which allows air in the jar and one in the front which allows the beads to fall into the brass block. The tube in the front can sometimes become frayed at the bottom from the constant flow of beads and the air blowing across the surface to move the beads out of the pen. This is normal, given the abrasive qualities of glass beads. Periodically, both of those tubes, especially the front, need to be replaced: (#09841 /5355 Air Hose 3 Inch Pkg. 2). Also, our department that repairs our dental laboratory equipment finds that the fittings that are on the brass block can wear over time, especially the top and front one leading to the pen: (# 09835 /5340 Male Connector ¼ Inch (see fig. 2).

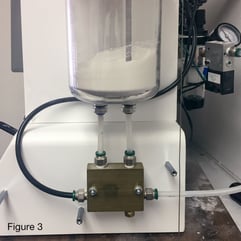

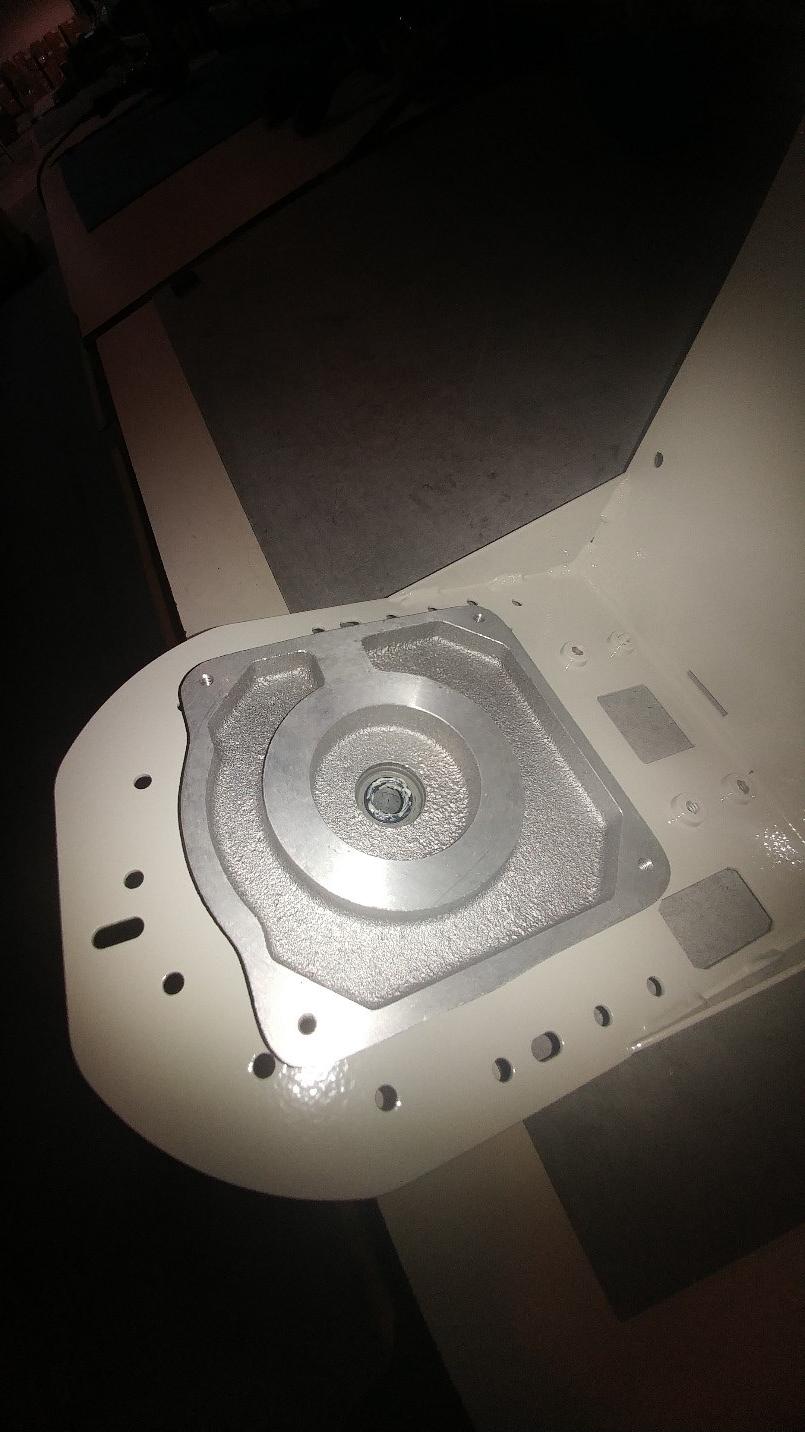

A little trick if you can’t order these two parts right away is to swap the front fitting and tube with the rear one. The rear ones are less likely to be worn and will often work better until new ones can be ordered. Important: Do not simply take the brass block off the side and turn it. The needle valve, visible by the hex nut at the bottom, should always be facing the front of the machine. The needle valve is essential to concentrate the bead flow and achieve the powerful stream needed to blast the rings effectively and efficiently. Even during routine maintenance when you take off the brass block to clean it, always make sure it is put back in the correct position. Note the block in the photo is placed incorrectly (see fig. 3).

A little trick if you can’t order these two parts right away is to swap the front fitting and tube with the rear one. The rear ones are less likely to be worn and will often work better until new ones can be ordered. Important: Do not simply take the brass block off the side and turn it. The needle valve, visible by the hex nut at the bottom, should always be facing the front of the machine. The needle valve is essential to concentrate the bead flow and achieve the powerful stream needed to blast the rings effectively and efficiently. Even during routine maintenance when you take off the brass block to clean it, always make sure it is put back in the correct position. Note the block in the photo is placed incorrectly (see fig. 3).

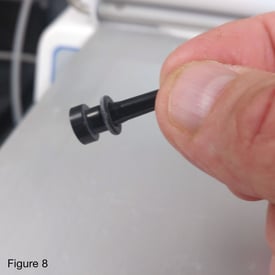

3. The last common area of concern is the hand piece and its black tubing. The o-ring should be replaced when worn and must be in the proper place inside the blasting pen: (#09818 /8517 Xcavator O-Ring (Pkg of 12). The tip should be placed in the pen cap first, with the o-ring on top of the tip (fig 4, 5, 6, 7).

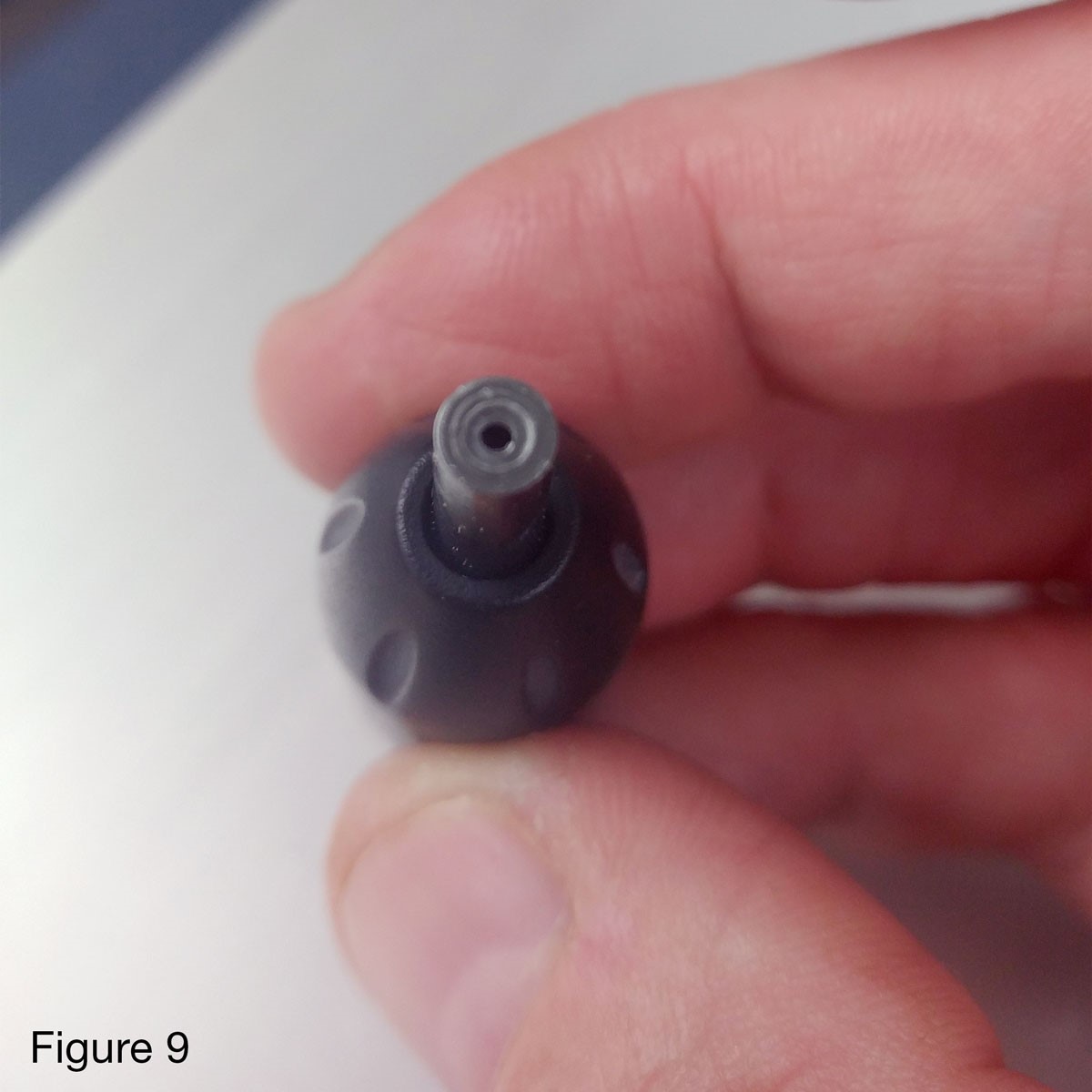

Insert the o-ring first, or the tip will cause blasting issues (fig. 8). The tip should be in good repair with its internal portion intact. A worn tip will not allow for effective divesting.If worn, it should be replaced with (#09807 /5332-1 Xcavator Nozzle Tip & O-Ring) (fig. 9). Finally, check the black hose leading to the pen for any cracks that could cause a loss of pressure and require replacement of the tubing: (#09832 /5332-3 Xcavator Tube 42 in.)

The very nature of the 50 micron glass beads make it imperative that we look at all these factors and some others, as moisture and obstructions make the beads clump and not want to move. These tips are a good starting point to getting your lab up and running should you find that your rings are not being properly divested. For additional information on divesting phosphate investments, visit www.whipmix.com.

Leave a comment