Porcelain furnace calibration is an often misunderstood and undervalued part of quality assurance maintenance. It is at very least a critical part of guaranteeing consistency in ceramic firing results.

All furnaces require a periodic temperature recalibration due to the effluents given off by the materials fired, including alloys, ceramics, investments, metal ceramics, stains and glazes. They are deposited on the platinum/palladium thermocouple and in some cases react chemically with the noble metals to affect the sensed temperature. Oxide layers can build up on the thermocouple through many cycles of vacuum and vacuum release and exposure to air. In addition, prolonged high heat can cause crystallization of the metals in the thermocouple and inhibit the transmission of the electrical signal to the computer. Lastly, the muffle heater wire itself can become brittle and scaly along its surface, especially after extended usage. This can affect the infrared spectrum irradiated by the heater wire and redirect the angle of the emitted photons so that the ones striking the thermocouple create less of a charge on it. With a sub-charged thermocouple, the furnace computer may think that the temperature of the muffle is different than the actual temperature.

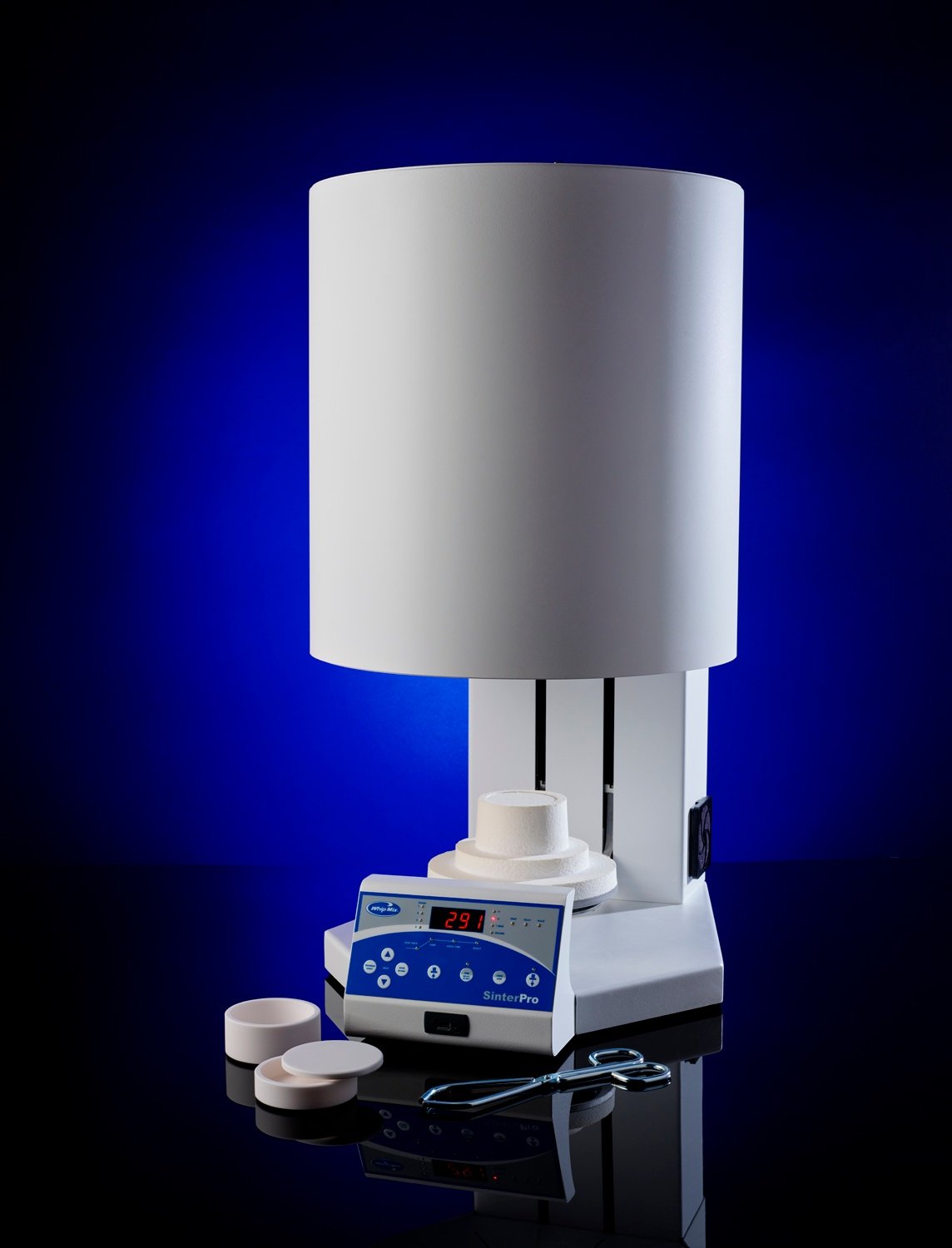

To address these frequent problems, Whip Mix developed a special calibration device called the ProCal.

Why use the ProCal?

- Whip Mix’s ProCal satisfies the need for an efficient, consistent method of checking not only on an individual ceramic furnace but an array of PRO furnaces.

- It is more accurate than the furnace itself.

- It offers an easy application of the information acquired by the instrument and is not subject to human interpretation.

- It places a second thermocouple into the muffle in a consistent position. This ensures consistent information readings.

- Each time the furnace is commanded to a specific temperature, it looks at that ‘target’ temperature, determines which calibration value is appropriate for that target value, then adds (or subtracts) the correlation value to produce the accurate muffle temperature.

With all of these factors involved in the operation of a ceramic furnace, it becomes obvious that these machines need regular maintenance, monitoring and care for long life and consistent results. With that in mind the ProCal Calibration device becomes an invaluable tool and partner in your success.

.jpg)

Leave a comment