e.MAX® has become a very useful and well accepted tool for dental restorations. Many dental technicians and clinicians are looking to use this material outside of the system recommendations of its manufacturer. This is entirely possible; however it does require some ‘dialing in’ of times, temperatures and technique. Seasoned ceramists will know that every porcelain furnace and the ceramic materials used need to be “calibrated” to each other for that perfect fit. Careful application of long standing ceramic techniques will give you the results you require.

e.MAX® has become a very useful and well accepted tool for dental restorations. Many dental technicians and clinicians are looking to use this material outside of the system recommendations of its manufacturer. This is entirely possible; however it does require some ‘dialing in’ of times, temperatures and technique. Seasoned ceramists will know that every porcelain furnace and the ceramic materials used need to be “calibrated” to each other for that perfect fit. Careful application of long standing ceramic techniques will give you the results you require.

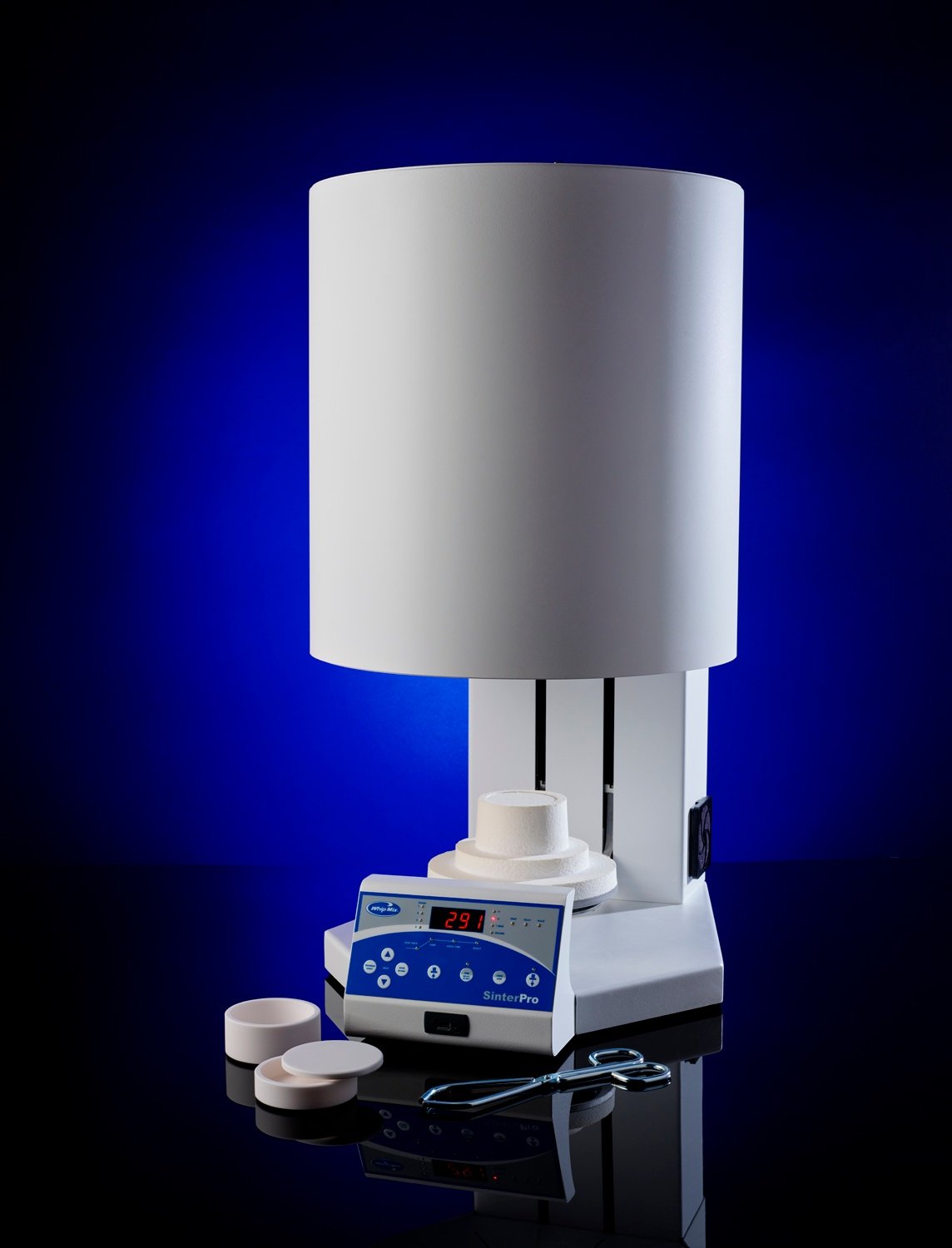

Here are are some useful tips for perfecting your lithium disilicate restorations using Whip Mix materials and pressing furnaces.

- You should set the e-max programs to a zero,’0’, cool time.

- Use of an AlOx (Aluminum Oxide) plunger will rob 10°C from the internal temperature. You may need to add these 10 degrees to the top end temperature.

- If you get a cold press (like a cold casting), increase the temperature by 5°C. If this does not work, increase the top temp hold time by 5 minutes. If this does not work increase the top temp another 5°C.

- BURNOUT!!! Make sure that the temperature is at least 1560°F (850°C) and that you burnout for one hour minimum. Add 10 minutes for each additional ring you have in the burnout oven (one ring, one hour; two rings, one hour and ten minutes before casting the first ring).

- If you get a reaction layer, reduce the press time in 15 second increments, until it is very light or you get a miss-press.

- Always use the INVEX Liquid from IVOCLAR. This cleans the reaction layer off of the pressing and gives you a good surface.

- If you get cracking in the glaze, you do not have the entire reaction layer removed.

- If you try to press more than 2 ingots you may run into the top of the muffle with the press plunger. This will give you a “Lift Obstruction” or “Vacuum” error. Reduce the plunger length by ½ the length of an ingot.

- Investment in silicone rings can trap moisture and cause cracks or top blowing in the rings. Remove the investment from the ring at the correct benchset time, then benchset another 5 minutes for a 100g ring and 7-10 minutes for a 200g ring, depending on the humidity.

- If you have been unsuccessful with your pressings, call your technical support representative and work through the problems. Every pressing furnace can press this material.

Please note that these tips provide are only a starting point and may need to be modified for your laboratory conditions.

.jpg)

Leave a comment