In the world of pressable ceramics there are many options and many combinations including monolithic, press to metal and press to zirconia. All can provide excellent options for an aesthetic long lasting dental restoration. Technicians often are called upon by the doctor to give advice on what type of restorative material might be best offered for patients based on their particular dental needs.

In the world of pressable ceramics there are many options and many combinations including monolithic, press to metal and press to zirconia. All can provide excellent options for an aesthetic long lasting dental restoration. Technicians often are called upon by the doctor to give advice on what type of restorative material might be best offered for patients based on their particular dental needs.

Some things to consider when fabricating a pressable ceramic restoration are: is the material resilient enough for where it is being place and if so is the preparation sufficient for a successful restoration? This is where communication between the lab and the doctor is key. If the entire criterion is met for fabrication, a material will need to be selected. Should the restoration be a leucite based or lithium disilicate based ceramic? Whatever material is chosen it is vitally important to follow the ceramic manufacturer’s instructions in regards to waxing or milling, spuing and investing. Once invested it’s important to take special care to allow for sufficient burnout before the pressing process.

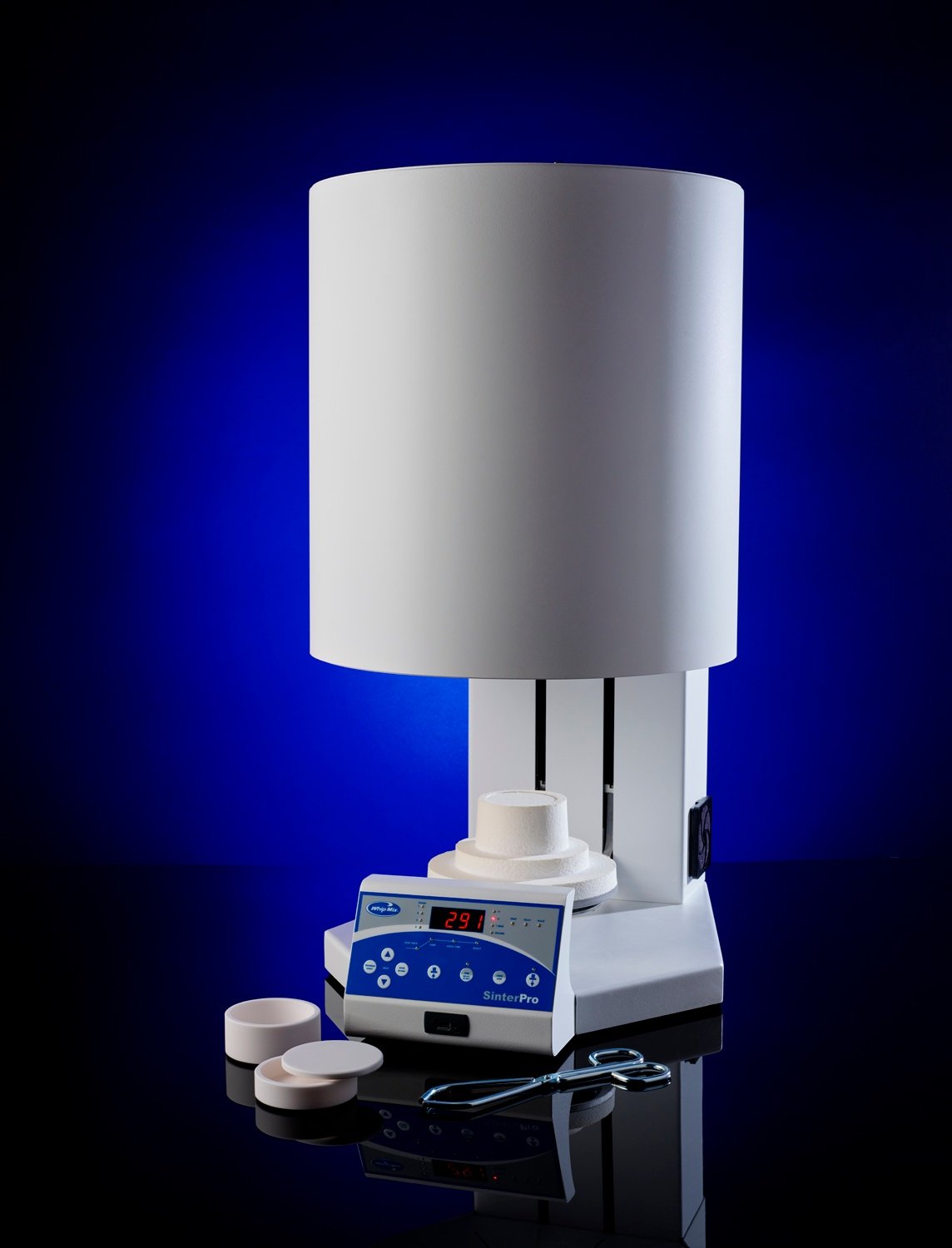

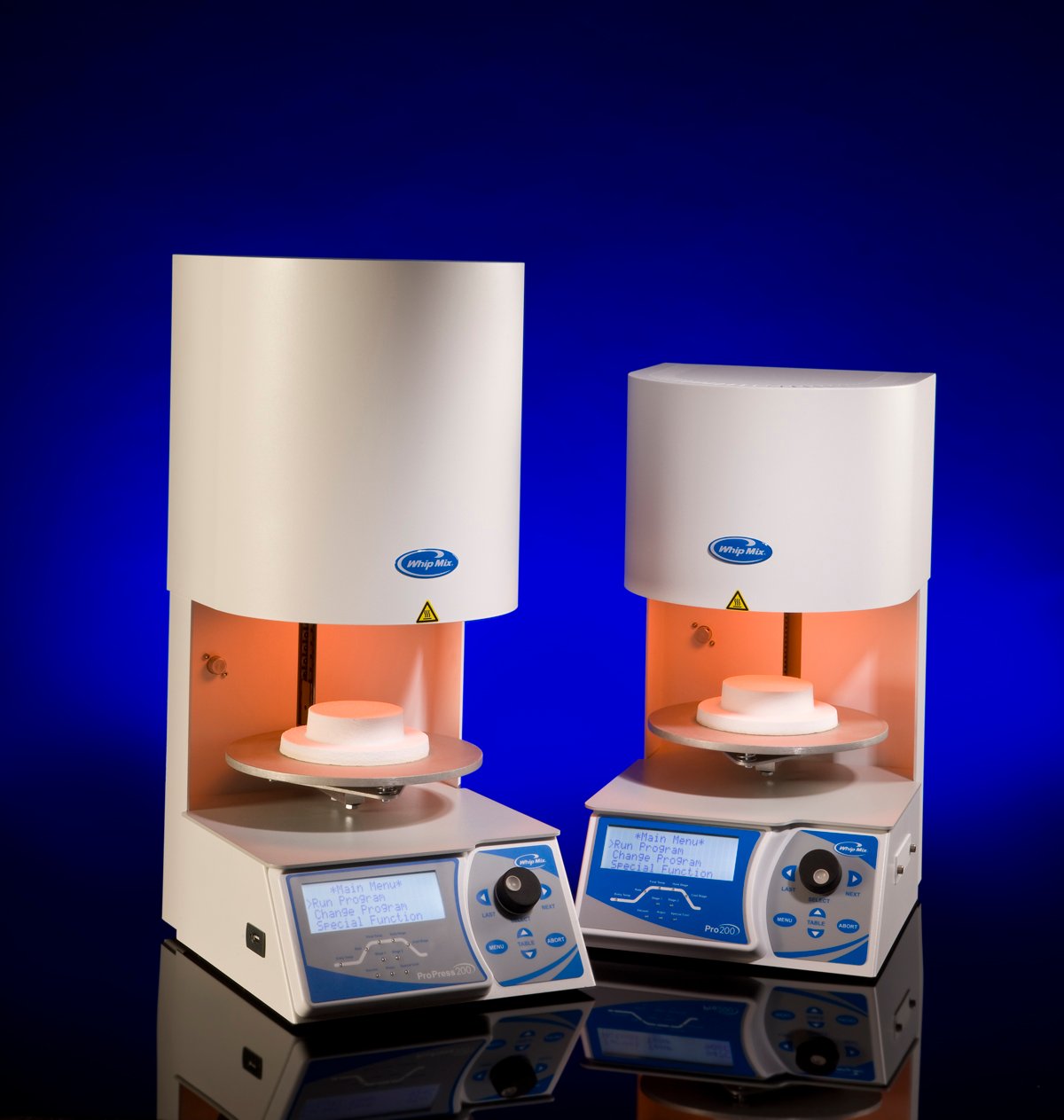

From the burnout, it is time to bring your ring to the pressing furnace, insert your ingot, and plunger and press your ceramic. From time to time the pressing may come out short or have a greater amount of reaction layer than desired. Many factors could be the cause of a marginal or failed pressing. Many would tell you that it is the fact you didn’t use the glass manufacturer’s oven. This is simply not the case. While it is true some manufacturers have their glass “dialed in” for their brand of pressing furnace, this doesn’t mean their oven is your only option. While it is true you want to follow the glass manufacturer’s instructions before pressing, once you get to the actual pressing it is really about time and temperature. Time in regards to how long you have burned out as well as how long the ring was held at high temperature in the pressing furnace. Temperature; first as it relates your burnout, was it hot enough and once put into your pressing furnace is the hold temperature hot enough? When these factors are considered, if you are using a pressing furnace not made by the glass manufacturer, it is simply a matter of experimenting to get the right amount of press time put into your formula.

The point being; don’t believe the myth that you have to have a special oven to press a particular glass. Just like with conventional ceramics that can be fired in any porcelain oven, so too can pressable materials be pressed in any press furnace. It is a matter of patience and trial and error to focus in on the correct combinations to get a successful pressing. Many great technicians are out in the field doing this every day with great results so be methodical and you too can achieve restorations you can be proud to offer to your doctor and patients.

Leave a comment