The Vac-U-Mixer is the complete assembly consisting of the lid, paddle shaft assembly and bowl. Since it is such a workhorse in the lab, its preventative maintenance can sometimes be overlooked. Staying on top of a regular routine service schedule will prolong the life of equipment and ensure minimal production downtime.

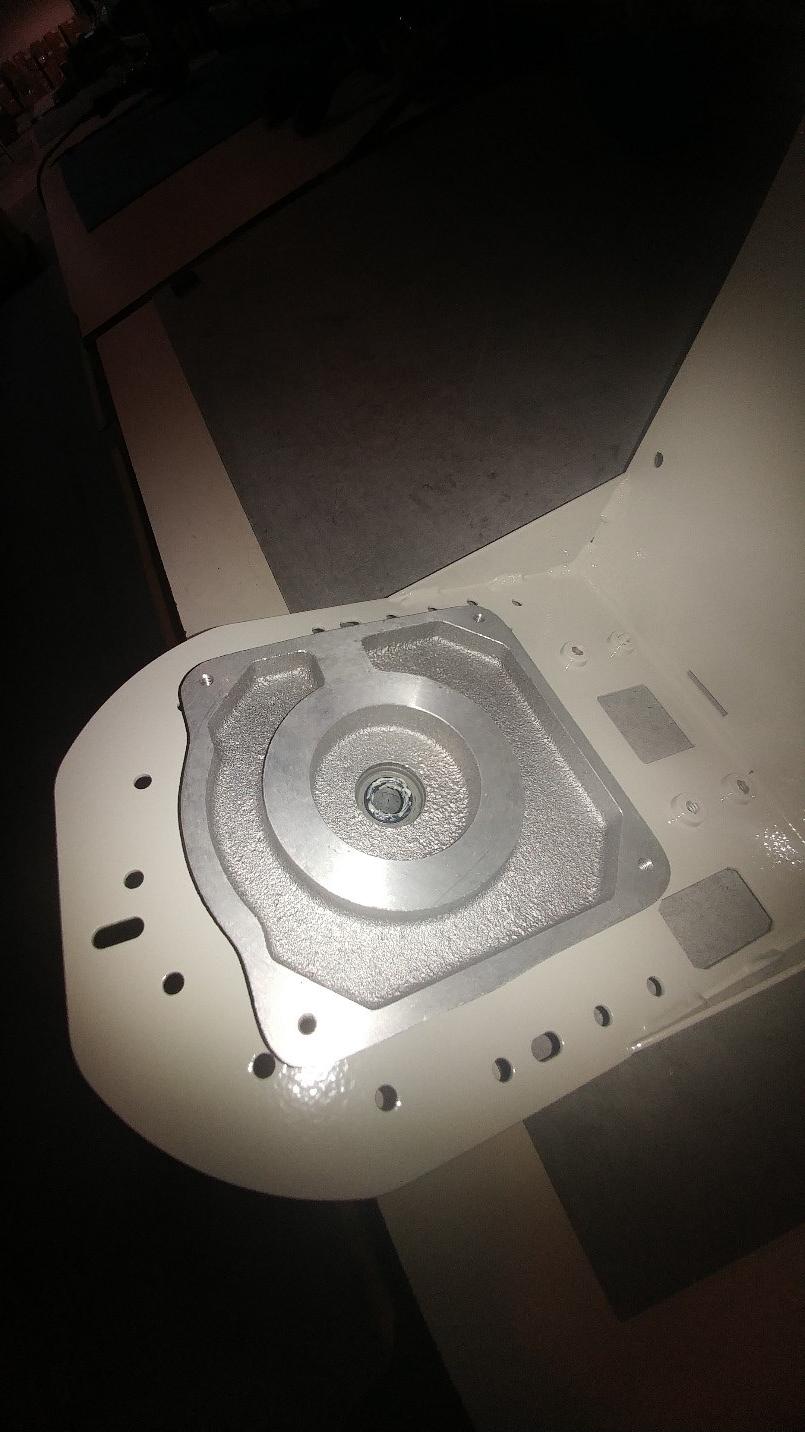

General maintenance of the Vac-U-Mixer can begin by unscrewing the paddle assembly from the lid in order to clean and lubricate the paddle assembly and the lid. To do this, simply hold the paddle in one hand and insert a lab knife into the slotted drive nut at the top of the lid and paddle assembly. Turn to unscrew the drive nut. Once that is off, the paddle assembly should be pulled out from the bottom of the lid. Examine the paddle to make sure it isn't bent. By rolling it on a table edge, you can observe how it spins and determine if it is spinning true. If it is bent, you will need a new paddle assembly. However, most of the time that is not the case and it simply needs to be cleaned. To clean it, a soft cloth with rubbing alcohol will be sufficient. If the buildup of stone and debris is extreme, you may want to remove the two o-rings on the shaft and blast it with glass beads. Wipe off the paddle assembly completely and replace the o-rings with new ones.

It is also a good idea to run a cloth through the nylon bearing (hole) in the lid to clean out any buildup of grime. Also, be sure to clean any debris off the lid using a gentle cleaning agent such as Simple Green. At this point, it is a good idea to remove the large o-ring that seals the lid to the bowl. If it looks deformed or damaged, it should be replaced. Once the o-rings are back in place and the lid is clean, you can apply the Lubriplate. Lubriplate is lithium grease designed for the Vac-U-Mixer. It should be applied to the paddle assembly, the nylon bearing in the lid and the large o-ring for the lid. Wipe away excess grease.

Reassemble the paddle assembly and lid. Insert the large o-ring into the lid, screw on the drive nut and you are ready to use the Vac-U-Mixer again. Following these steps and replacing the o-ring at least annually will ensure smooth operation during the mixing process.

.

Leave a comment