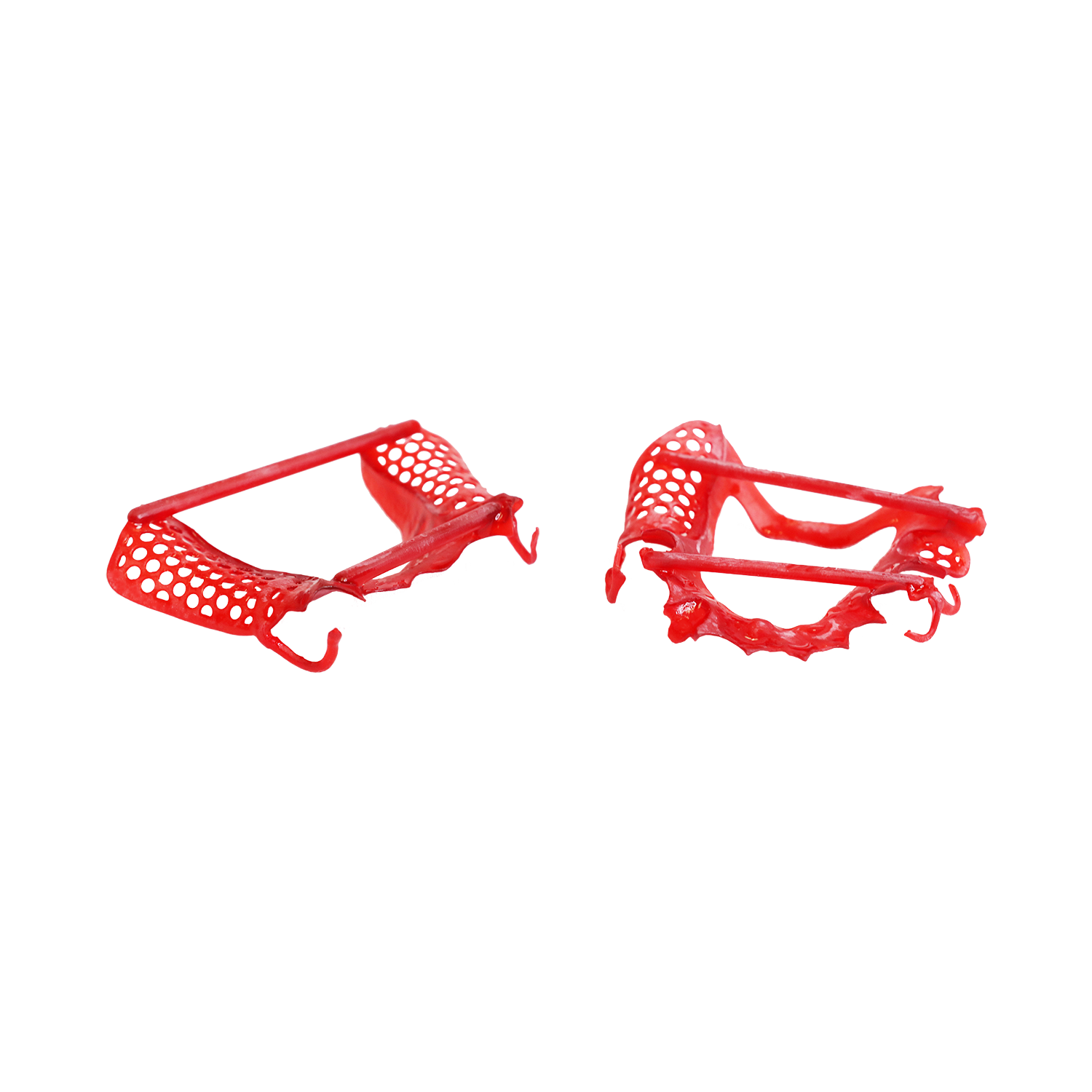

As many of you may know, Whip Mix has been manufacturing gypsum for 100 years. At our core, we are a chemical company. Now, we hire different types of chemists. Our photopolymer chemists develop our 3D printable resins, which have taken us from Figure 1 to Figure 2.

Taking the Lab and Clinic out of the Stone Age (Literally)

Fig. 1 Fig. 2

In Part 1 of this blog, we covered the different types of 3D printing, which can help you to decide which one best fits your business model. Of course, there are other considerations when bringing 3D printing in-house, or even just stepping up to a larger production printer. First, familiarize yourself with the terms used in 3D printing.

Quality of parts (XY Accuracy) Often times we hear that a printer prints at 25, 50 or 100 microns. Those numbers refer to the Z resolution, which is the controllable layer height (thickness). This defines the quality and detail of the printed object. By modifying the Z resolution, you can find a compromise between surface quality and print speeds. The quality of the part depends on the X,Y accuracy. The X, Y precision will depend on the type of 3D printing technology that you are using. The accuracy of a DLP 3D printer is defined by the size of the pixel being projected. The smaller the pixel size, the higher the accuracy.

Cycle time of the technology - How long it takes to complete a printed bed of parts

Yield of the technology - How many models can you fit on a print bed at once

Equipment uptime

- Change over time (From one material to another)

- Preventive Maintenance (Calibration, Cleaning Print Heads)

Cost analysis

- Purchase Price

- Maintenance Cost

- Annual Maintenance Program with Manufacture

- Uncovered Parts

- Cost of Downtime

- Contingency Plan

- Consider how much it will cost to train your technicians

Materials Consider your total cost to print a model, including the resin, tray, and support material, if needed. Also, if it is an open source printer, you can use any resin (this is why we partnered with Asiga. They are a true open source printer). If it a closed system, you are required to use the resins from the printer manufacturer.

Integration Analysis

- Facility Considerations

- Space

- Infrastructure

- Utilities

- IT

Operator Considerations

- Competency

- Training

- Capacity

Another consideration is that you will most likely need to add to your CAD software package. All of these printers come with software, but only nesting software. If you are buying a printer to print models, you will need to add Model Builder (3Shape) or Model Creator (ExoCAD) to your design package. This is another cost to keep in mind when purchasing a printer.

If you are considering buying a 3D printer because you are starting to get a fair amount of digital impressions and just want to print models, keep in mind what you may want to print in the future. A lot of companies are developing resins for 3D printing, including Whip Mix, Dreve, Keystone, Detax, Dentca and others. Also, keep in mind the FDA regulations on materials that require some type of class registration. If you look at clear materials as an example, most clear resins designate themselves as a Class IIa biocompatible material. This is a classification from the European Union (EU) and European Free Trade Association (EFTA) and has absolutely nothing to do with the FDA. At Whip Mix, we are very proud to have manufactured VeriSplint, the first FDA Approved Class II with a 510k-cleared (clear) resin for manufacturing splints, night guards/bite guards etc.

If you are considering buying a 3D printer because you are starting to get a fair amount of digital impressions and just want to print models, keep in mind what you may want to print in the future. A lot of companies are developing resins for 3D printing, including Whip Mix, Dreve, Keystone, Detax, Dentca and others. Also, keep in mind the FDA regulations on materials that require some type of class registration. If you look at clear materials as an example, most clear resins designate themselves as a Class IIa biocompatible material. This is a classification from the European Union (EU) and European Free Trade Association (EFTA) and has absolutely nothing to do with the FDA. At Whip Mix, we are very proud to have manufactured VeriSplint, the first FDA Approved Class II with a 510k-cleared (clear) resin for manufacturing splints, night guards/bite guards etc.

There are a lot of printers on the market today to choose from, and the key to getting a printer that will fit your needs now and in the future is to find a knowledgeable reseller to work with. Probably the most important purchase consideration is strong technical support. These are the people you will be counting on after you have purchased your printer. It is an exciting time in the dental industry and we are only at the beginning of where we are going with 3D printing. According to a 2018 report from SmartTech Publishing, we will have a reliable and accepted solution for printed permanent restorations in 5 years. Hold on to your seats!

I love talking 3D printing. Feel free to reach out to me anytime with questions you may have.

.jpg)

Leave a comment