Lean manufacturing principles, practiced throughout most of the industrial world, are helping to make America competitive again. Whip Mix adopted Lean principles and implemented various continuous improvement initiatives over the past 25 years, and found that doing so, there has been a marked improvement in our efficiency and profitability.

If you are not familiar with Lean Principles – read this blog.

If you are familiar with Lean Principle, but have not acted – read this blog.

If you have have implemented Lean, you may still get some nuggets of value, so read this blog.

Now is the time! Many lab owners/managers that I have talked to understand the benefits of implementing Lean Principles but think it might be too much for them. They have 20 – 30 years of cobbling and morphing together processes and to streamline them now seems overwhelming – like turning an aircraft carrier. With the adoption of new digital technologies to make dental restorations – now may be the perfect opportunity to start fresh and optimize your efficiency from the start. Even if you are not going to invest in digital technology, and plan to do the best you can for a couple more years, then implementing Lean principles is a low cost way to get more out of your existing processes.

Reasons for not implementing Lean principles include:

- It’s too hard. (like turning an aircraft carrier)

- It’s too complex. Not all of the tools used for Lean improvement are user-friendly

- I don’t understand the terminology. Muda, Mura, Kanban, Kaizen – Huh?

- It only applies to manufacturing. This came out of the Toyota Manufacturing system and only applies to making cars.

- I’m doing OK. It is not worth the extra effort to make a few more bucks or keep all of my doctors.

This is the first in a series of blogs I will provide that will help simplify Lean and provide easy to use tools and techniques that will help you identify and eliminate waste, improve workflow, and provide superior value to your customers (and your bottom line).

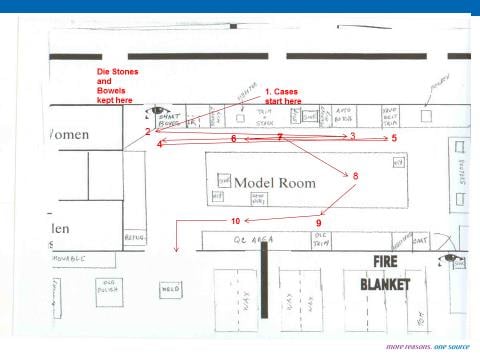

For example, one of the five Principles of Lean is to “Make the Process Flow”. Poor flow creates wasted movement and a chance for errors. Have you ever looked at the actual movement of cases through your lab? A simple tool to use is a Spaghetti chart. In the example below, we simply used the emergency exit map and documented the flow of a case through the model department. Once the situation becomes visible, it is easy to see where there are problems and move things around to provide better workflow. When asked why we have a given flow the typical answers are “that’s the way we have always done it” or “that’s how I was told to do it”. From my experience, lab supervisors or managers are often unaware of the actual workflow and inefficiencies that may exist.

Watch for future Whip Mix blogs that go into more detail about Lean Manufacturing Principles and how they can effectively enhance your efficiency and profitability.

Leave a comment