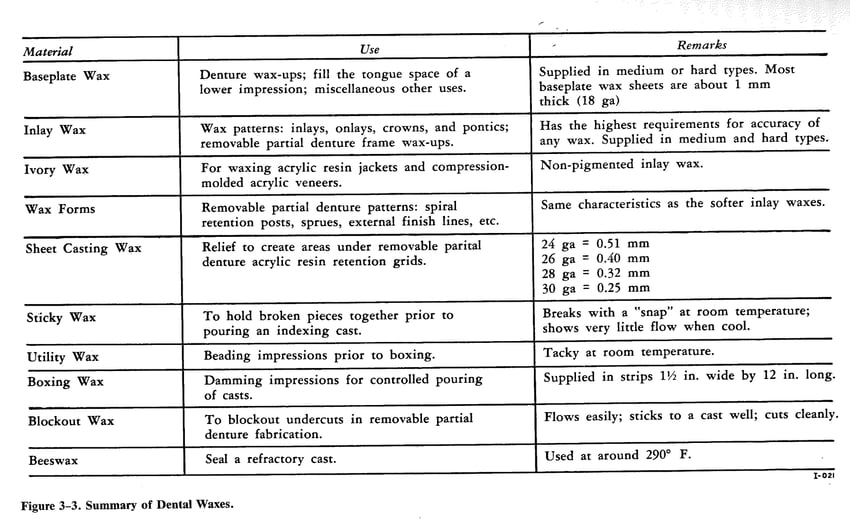

There are a number of different waxes used in the dental industry and how and when you use them is determined by a number of factors. One of the most common ones is consistency. If you are doing fixed work or removable, you’ll choose your waxes accordingly. Some examples of the commonly used waxes taken from The United States Air Force training publication AF Pamphlet 162-6 are listed below. The manual is considered by many as the go-to resource for laboratory instruction.

Wax compounds are composed of both natural and synthetic ingredients. Some of the more common ingredients are beeswax, paraffin, vegetable and mineral waxes, and organic coloring. Whip Mix waxes do not contain animal products. All of them are plant-based organic compounds.

Many technicians will use waxes to build a restoration starting with the highest melting range wax and finishing with the lowest. For example, a fixed technician might start by blocking out the die with a block out wax that melts around 205°F +/- 5°F. Next, a layer of dipping wax would provide a uniform internal surface for the substructure. This wax would have a lower melting temperature of approximately 180°F +/- 10°F. The next stage would use carving wax for the buildup. Typically these layers would have a melting temperature of 165°F =/- 10°F. Finally, a margin wax with around 165°F +/- 5°F would be used. Of course each variation in the molten wax state yields a different consistency. The use of wax pots and some environmental factors in a lab can also play a role in the wax’s viscosity and handling. This is but one example of how subtle additives in each type of wax can yield unique properties for successful fabrication. These options give technicians choices to complete any restoration.

Leave a comment