Generally, temperature issues cause incomplete castings. We often hear “it was not burned out all the way”…but really what do you think would happen to residual wax when alloy at over 900º to 2000º F touched it? The true answer is that either the mold or the alloy were not hot enough. Since we are looking at the alloy, and we can see that it has become molten…it's probably hot enough. We cannot see if the glass is hot enough to press, but the results tell us if it is.

So, let's look at the investment temperature. Let's even assume that the oven is actually at the temperature that the read out indicates. Although I would venture to say you probably do not remember the last time that you actually calibrated the furnace.

The larger the mass of the object you are trying to heat, the longer it takes to heat. Therefore, at a fixed temperature, a 300 gram ring takes longer to heat than a 100 gram ring. The same is true if you put four 100 gram rings in the oven at the same time. The rule is that you add 10 minutes of burnout time for every additional ring. So if one ring requires 30 minutes of hold time; four rings would demand . . . that's right, 60 minutes. No, you cannot just increase the temperature.

Rings do not automatically heat up at the same rate that the air in the oven heats up. The thermocouple (TC) is reading the temperature of the air, not the inside of the ring. The rings lag behind, so we hold them at the top temperature so that the temperature can catch up in the inside.

Example: you have a short, rounded casting on the margins, but the button is sharp edged on the outside.

The alloy was hot enough, but the internal part of the mold was not. The mold pulled the heat from the alloy and stopped it in its tracks.

The same is true for pressed glass. Short rounded edges mean a cold mold. Not necessarily the need for more press pressure or more press time. Try increasing the hold time five minutes, then the temperature five degrees and then the hold time another 5 minutes until you succeed.

Example: If the button has rounded edges, and you have rounded edges on your margins, then the alloy or glass was not near the required casting or pressing temperature. Re-think how you are delivering heat to your button or alloy.

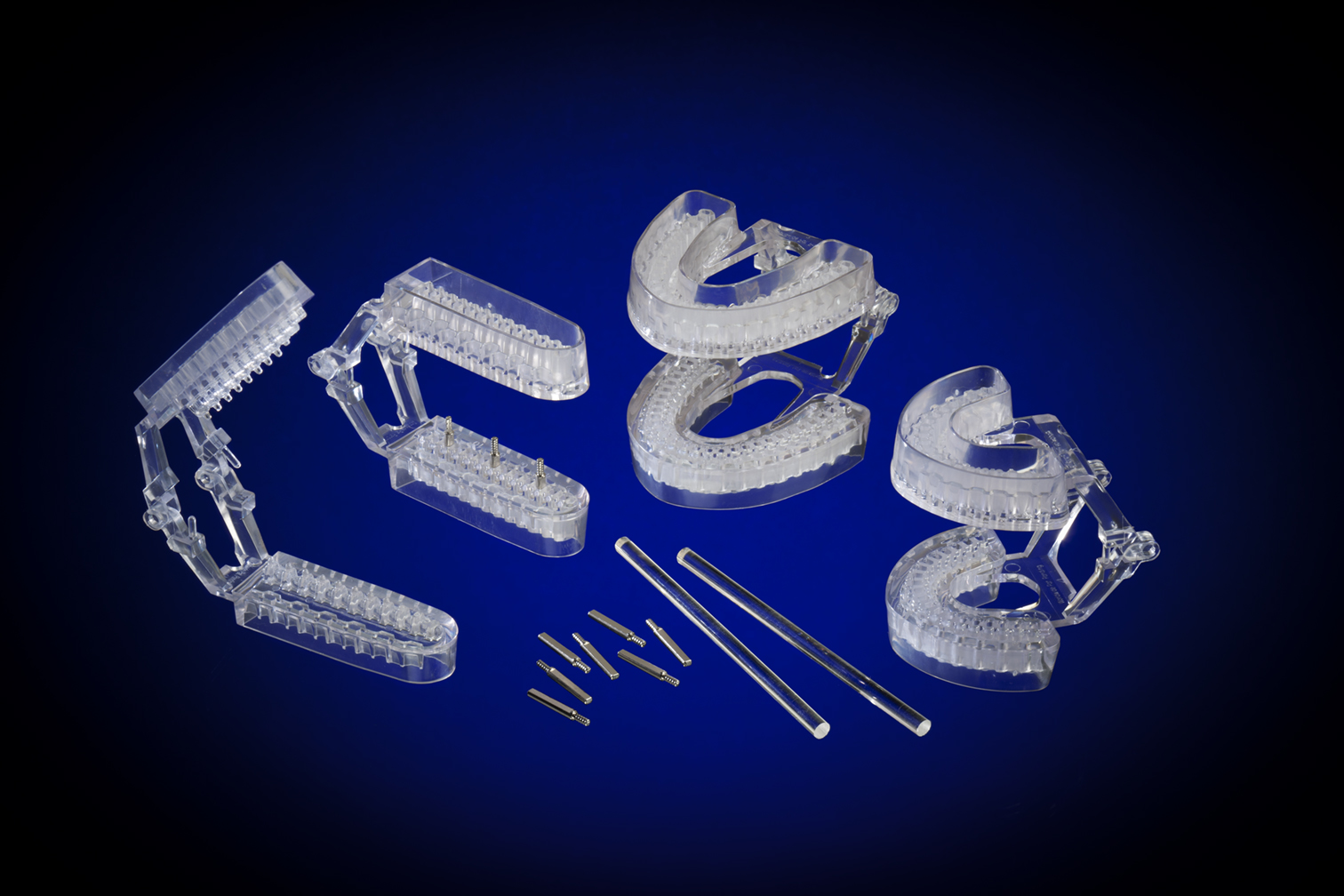

Now, pull out the silver strips or Tempills, and check the calibration of the burnout oven. You may find that it is way off. If it's right on the temperature, then you are going to have to change your process for casting and pressing to find success.

Leave a comment