Pressed ceramics and their accompanying furnaces have now been around for 25 years. Some of the furnaces used to create the desirable pressed restorations do it consistently well while others may not. In addition, some offer a number of attractive, but sometimes unnecessary features.

Pressed ceramics and their accompanying furnaces have now been around for 25 years. Some of the furnaces used to create the desirable pressed restorations do it consistently well while others may not. In addition, some offer a number of attractive, but sometimes unnecessary features.

What is important with these types of furnaces is temperature accuracy, adjustable pressing speed, pressure and the sensing and control of the glass flow. Why would a furnace have to ‘sense’ the flow of the molten glass? Because if you use a furnace with set parameters (and sometimes you don’t even have control of those settings), you do not have control of the pressing process. There are certainly times when you are pressing a simple ring with one or even two units, where, a factory setting will most likely produce a complete press. But, there are also times when the patterns in the ring are in a more challenging configuration. You need control then because pressings can often be incomplete or take longer. You may need to slow down the ramp rate, the pressure or even the speed of the press rod and plunger.

You’re in Control

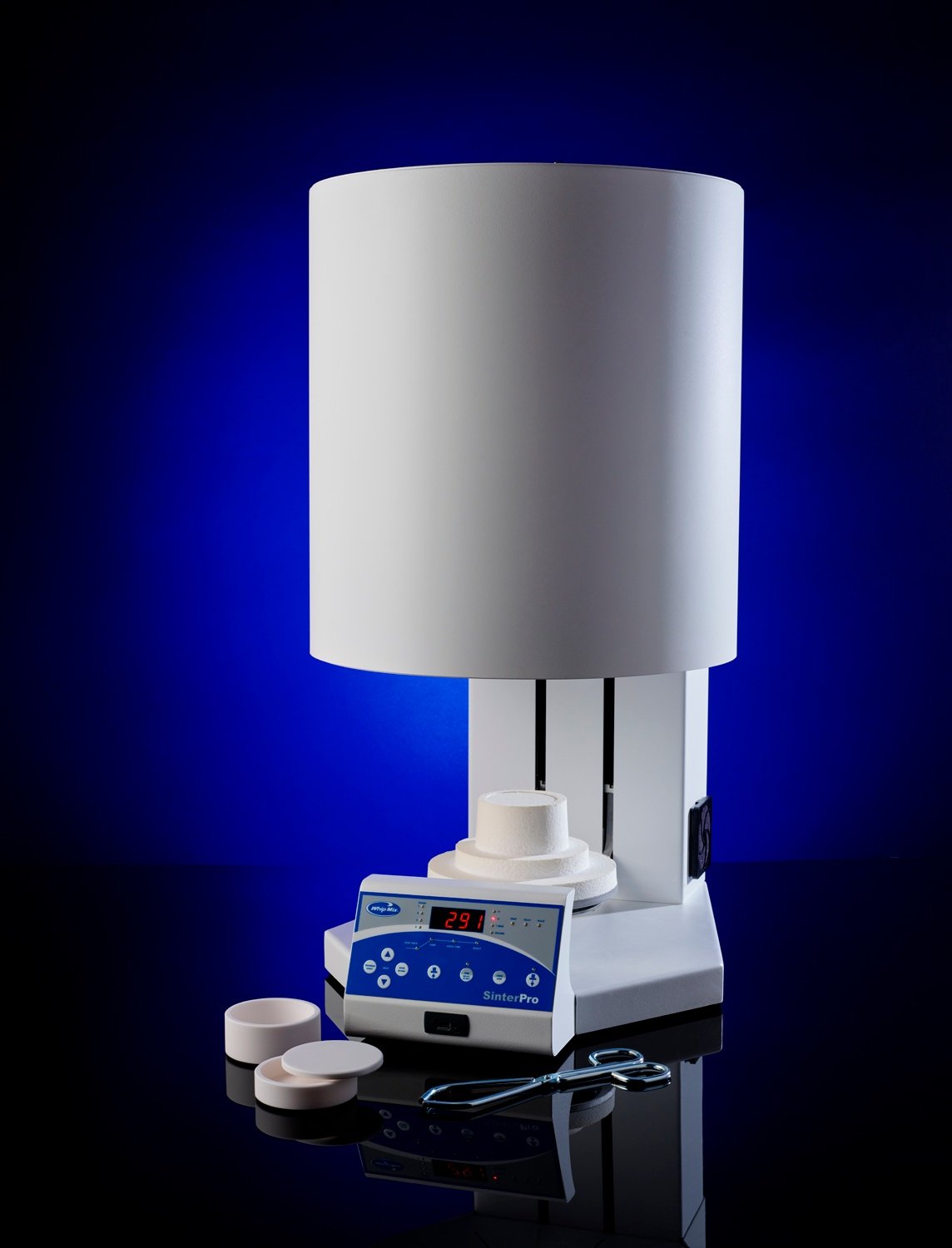

Whip Mix’s ProPress SP (Sense Press) Furnace was designed to allow the technician to have full control of the pressing process. A unique component monitors the flow of the glass and senses the movement of the ceramic into the ring in real time from start to finish. When the mold fill is complete, the table is lowered immediately. The ProPress SP’s faster pressing not only saves time, but also minimizes the formation of a reaction layer.

To Press or not to Press?

Have you ever looked at the bright red line in the mold just after you removed it from the burnout furnace and felt that sinking feeling? A big crack in the investment! Now what? Well with other press furnaces, you would have no choice but to place it in the pressing furnace, cross your fingers and your toes and wish for the best. Sometimes you win. Sometimes you don’t.

However, with the ProPress SP furnace, it is actually able to press cracked molds successfully. This unique, selectable feature increases the likelihood of a complete press by sensing the controls it needs to fill the mold and backs off to the ideal speed and pressure. The molten ceramic is then eased into the mold until it is completely filled.

Porcelain, too?

Due to its advanced electronics, this unique furnace also fires your powdered porcelains very accurately. In fact, the furnace comes with PC software that contains over forty porcelain firing schedules for your convenience. Find the porcelains you use and simply upload them into your ProPress SP. The furnace does the rest.

So, when thinking about what furnace will enable you to control it, instead of having it control you, be pro-active with the ProPress SP Pressing Furnace.

.jpg)

Leave a comment