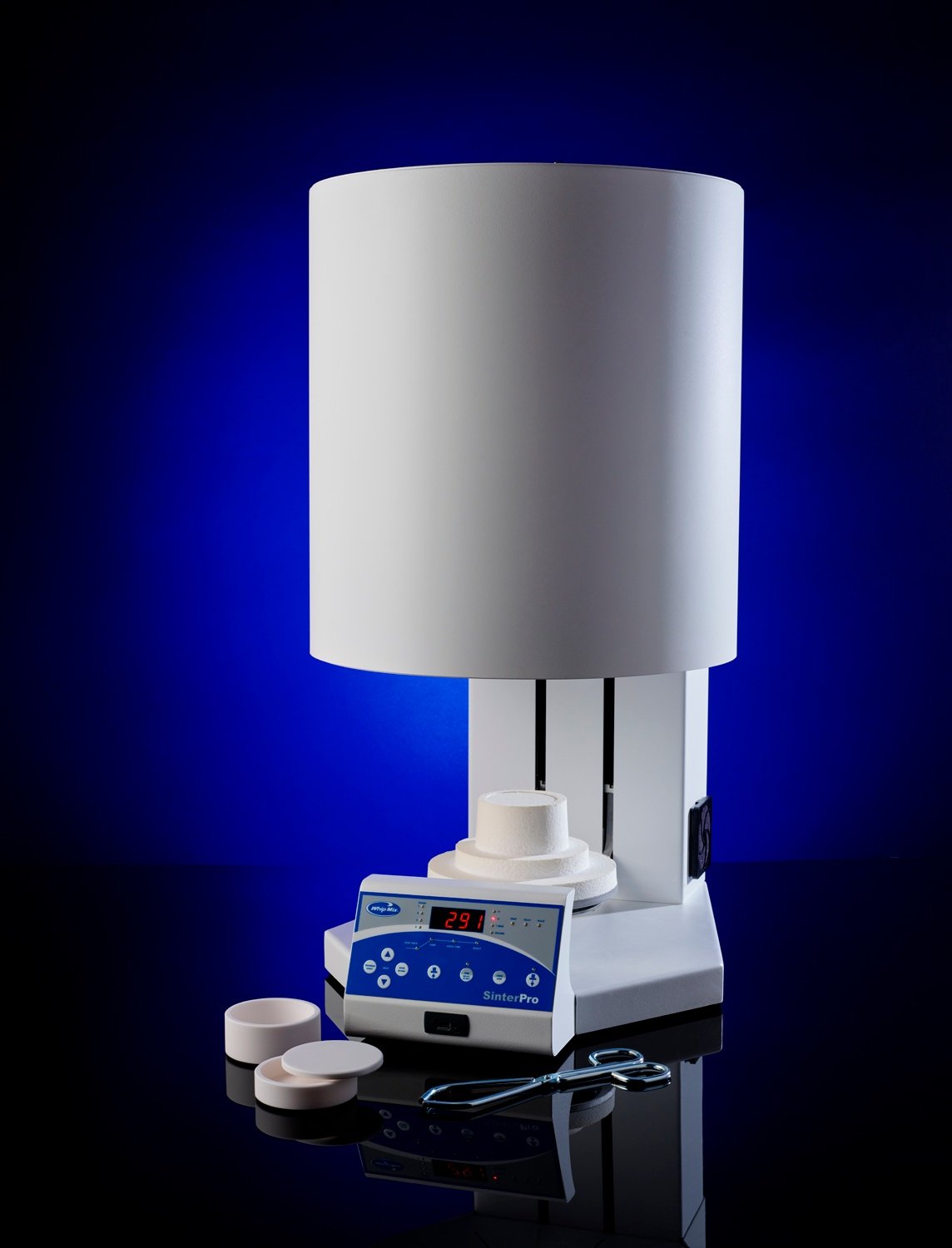

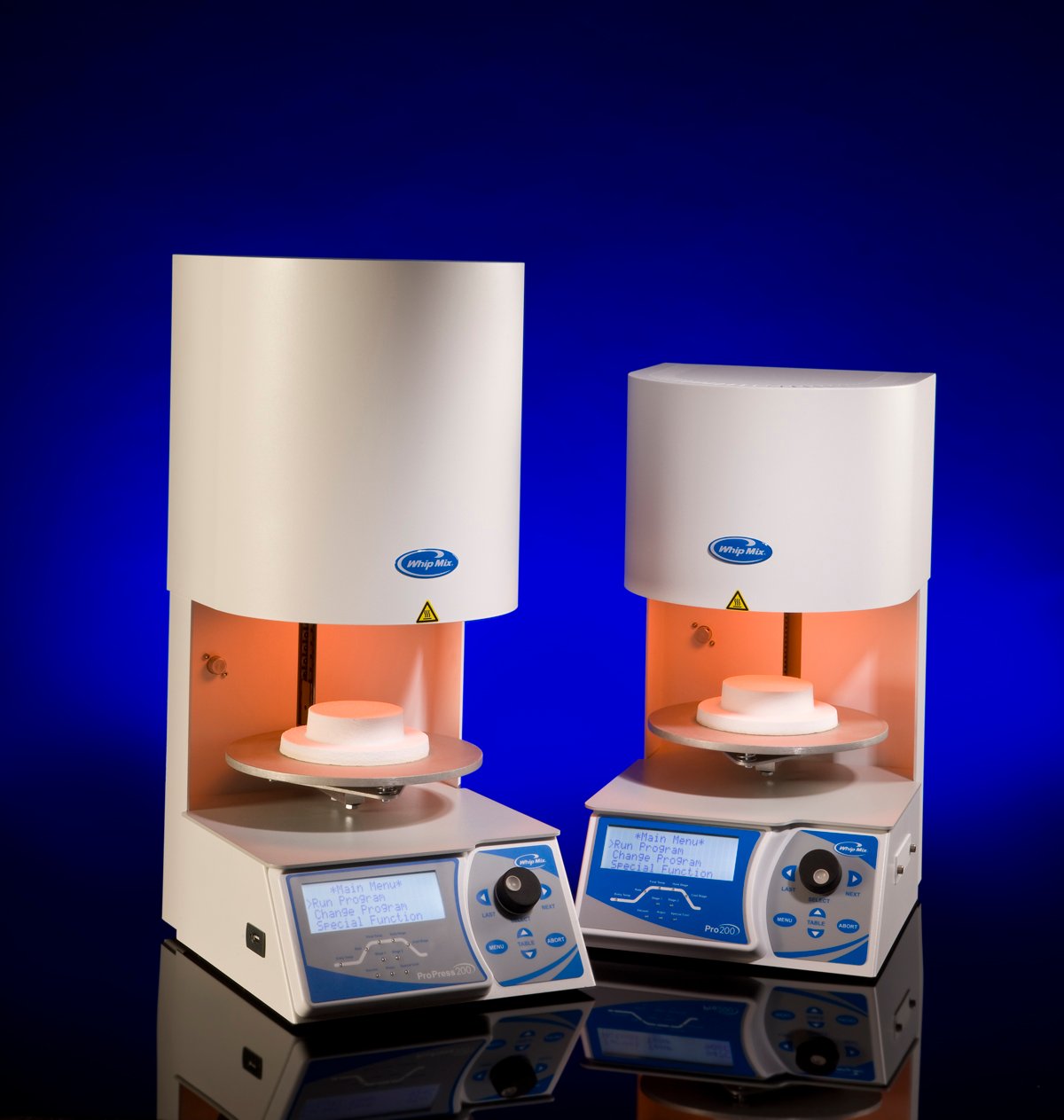

.jpg?width=287&name=SinterPro-2017%20(1).jpg) Differences in sintering furnaces are not just based on brand and price. Heating elements, number of programs, heating chamber configurations, sintering speeds, and even unit size all vary somewhat. So which unit is best for your dental lab?

Differences in sintering furnaces are not just based on brand and price. Heating elements, number of programs, heating chamber configurations, sintering speeds, and even unit size all vary somewhat. So which unit is best for your dental lab?

The driving force behind newer furnace designs and capabilities is the growing number of zirconia materials and their required sintering parameters. Most zirconia materials are sintered at or below 1,550⁰C with a slow heat rise (4⁰C - 10⁰C per minute). Some zirconia manufacturers are recommending lower temperatures and some higher.

Proper Temperature

It should be noted that recent studies indicate that firing at approximately 1500⁰C - 1550⁰C (depending on the temperature accuracy of the furnace) produces maximum strength in zirconia and that firing above and below the recommended temperature by just 150⁰C can result in lower strengths due to grain growth. A specific case in the study showed that strength drops from about 1280 MPa at 1500⁰C to about 980 MPa at 1600⁰C and only about 600 MPa at 1700⁰C.

In addition, a higher temperature may result in lowered stability and uncontrolled transformation, causing cracking of the zirconia. And that’s just the physical property changes. Temperatures that are too high for the material also cause a lowering of translucency. Higher is not always better! Sticking to the manufacturer’s recommended firing schedule is critical, as long as the manufacturer is reputable. Most yttria partially-stabilized zirconia materials attain their ideal physical, mechanical and esthetic properties at approximately 1550⁰C.

Furnace Features

If you are using more than one type of zirconia – or you are looking for varied results, depending on the patient, where in the mouth the restoration will be placed, etc., you will most likely want to purchase a furnace that offers you multiple programs multiple program stages and a way to control the cooling rate of your zirconia restorations.

Program Stages

Program Stages enable you to vary temperature, delayed starts, ramp rates and hold times to adjust your final result. Since most sintering cycles are fairly long, you may want to increase the rate rise from ambient temperature to the point where sintering begins, then throttle back in a subsequent stage to optimize the translucency. Why not save time during the run-up when nothing is happening to the material?

Capacity

Muffle capacity is another area that can be important, based upon your laboratory’s production needs. Some furnaces allow only one sintering tray to be used per cycle, many offer the space for two, but the ideal space will accommodate 6 trays vertically stacked, enabling the processing of 60+ units and even Prettau bridges.

Safety

Of all the features a sintering furnace may offer, perhaps the most important one is safety. After all, these furnaces climb to extraordinarily high temperatures and they hold there for a long time. And they use high amperage to do it. If you are concerned for the safety of your personnel and laboratory, be sure to buy and use a furnace that is UL Safety Certified to the UL 61010 standard. This means that an independent testing laboratory has confirmed that if the equipment fails, i.e. runaway temperatures, etc., it will do so safely. You have several good choices out there. When you’re ready to purchase one, refer to this article when you’re shopping for a good, effective and safe sintering furnace for your lab.

Editors Note: This post was originally published in November 2013 and has been updated for accuracy and comprehensiveness.

Leave a comment