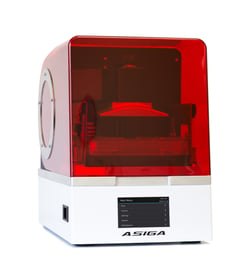

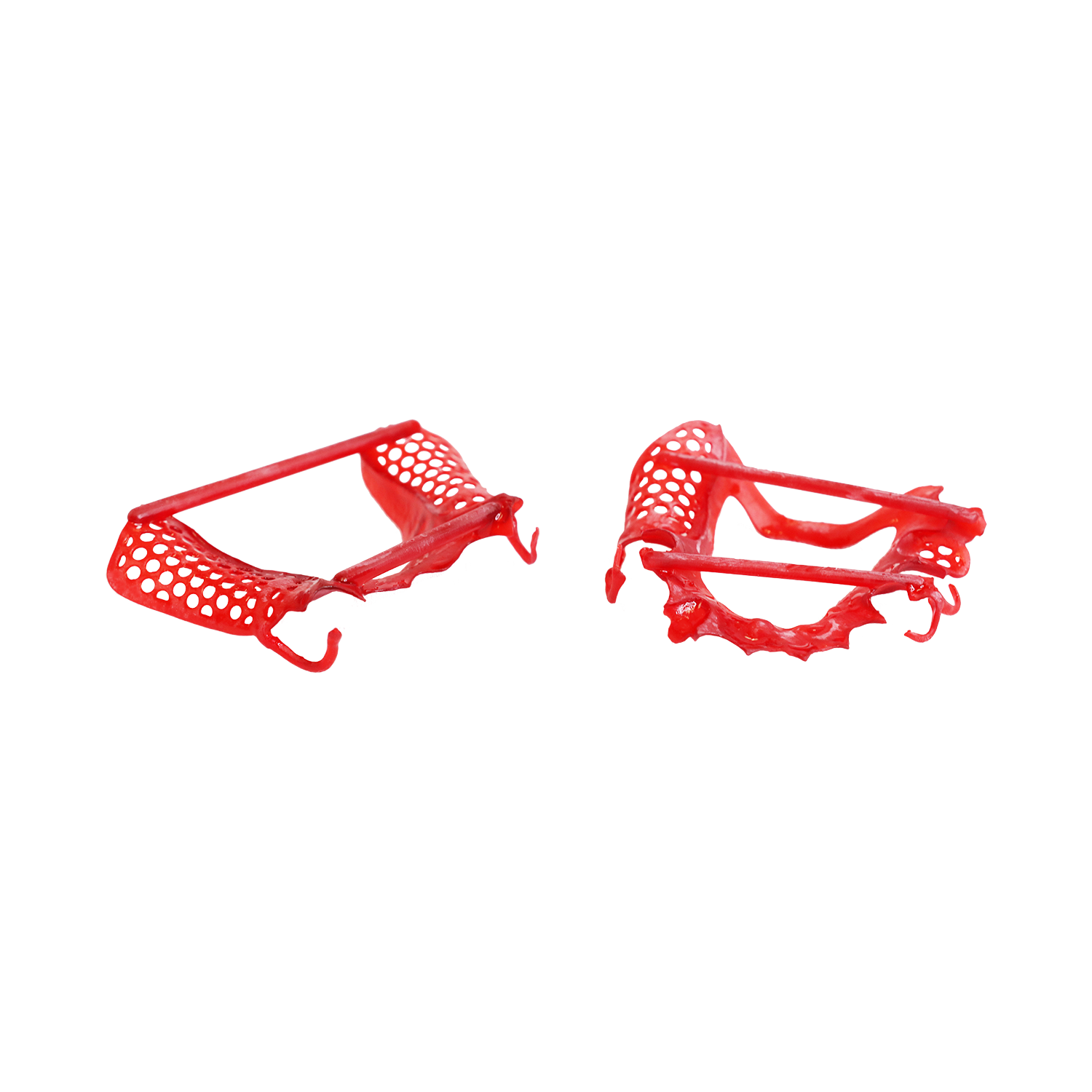

Last year, Whip Mix had our first Orthodontic Lab purchase the Asiga Max 3D printer. K&B Orthodontics Lab started in 1997 in Jane Hyatt’s mother’s basement in Connecticut. A couple of years ago, Jane’s daughter Kristen Benitez graduated college and decided to join her mom in their small two-person lab. It wasn't long before Kristen encouraged her mom to go digital, so in 2018 K&B decided to purchase their first Asiga MAX 3D printer. After 6 months of using it, they had to purchase another MAX in order to keep up with their new business. Of course, when you use printers, you also need to buy consumable items such as the trays & the resins. K&B purchases 6-8 liters per month of the VeriModel OS White 3D print resin from Whip Mix. K&B uses this versatile resin because it has the capability to produce very accurate orthodontic models. You can see the photos below of this high quality resin. Since K&B has attained so much growth in under a year, I thought others would want to hear how a two-person lab made that happen. I decided to interview Kristen, the Digital Specialist at K & B Orthodontics for my first Whip Mix Blog. Here is our interview below along with some photos of what they have been able to print on the Asiga MAX 3D printer.

Cherie: What type of orthodontic items are you printing for your doctors?

Kristen: When it comes to printing, we print study models, working models and horseshoe models for Essix retainers.

Cherie: How has 3D printing sped up your lab process compared to being analog?

Kristen: 3D printing has enabled us to have models at our fingertips. Instead of having to go to each office to pick up models, we are able to prep them and print them as soon as they come in. It saves us time and money, but it is also more convenient for the doctors’ offices. If a case needs to be rushed, they can send it to us right away.

Cherie: Have you gotten more business by having these MAX printers? (I know Jane has told me you have increased business, but by how many doctors?)

Cherie: Have you gotten more business by having these MAX printers? (I know Jane has told me you have increased business, but by how many doctors?)

Kristen: Before purchasing our first MAX, in December 2017, Jane went to pick up some work from a couple offices and only came back with three cases. At that moment, she realized that if she did not get with the times, she would ultimately have to shut down the lab. At that point, the lab only had about nine regular accounts. Fast forward to today, our workload has doubled in less than six months. We quickly realized that one printer was not going to be sufficient and decided to buy a second one. We now have 13 main accounts that we service in our area. Our business is definitely booming!

Cherie: Would you recommend that other Orthodontic Labs become digital and start using a 3D printer such as the MAX? If so, WHY?

Kristen: We definitely would recommend other orthodontic labs go digital for many reasons. The models are much nicer to work on. They come out clean and their accuracy is much greater, compared with stone. Additionally, they do not break as easily, which is a plus.

Also, your work is at your fingertips. As soon as you get something in, you can print it and have it ready from prep to curing time in a little more than an hour, depending on what type of model you are prepping. In addition, if something breaks, you can always go back and reprint the model rather than calling the office and having the patient having to come back in for another impression.

If your doctors have scanners, the choice is pretty simple. Purchase a printer. Your workload will increase almost instantly.

Cherie: Has owning a 3D printer increased or lowered your everyday lab costs?

Kristen: Owning a 3D printer has increased our everyday lab costs, because, as with any type of equipment, it costs money to operate and maintain. For our lab personally, we produce so many models that we go through a lot of resin and build trays. But, this is something everyone has to go through when investing in a company. We are just learning how to best offset the costs.

Cherie: Has owning a 3D printer given you more free time to work on more cases? Or has it slowed down your production?

Kristen: I would say that, initially, having a 3D printer slowed down our production because we were still learning how to work with the models and how to operate the software. Now, we've realized that we are able to get more done due to less waiting time. Plus, we don't worry about things breaking anymore.

- Watch the webinar below to learn more about 3D printing and how it can help your lab!

.jpg)

Leave a comment