Are you having trouble getting good fits between your titanium custom abutments and crowns? Are you tired of using messy CAD spray to capture your abutment designs? If you have answered yes to either of these questions then don't need to worry, 3Shape’s “Split File Design” feature will solve all your problems.

Are you having trouble getting good fits between your titanium custom abutments and crowns? Are you tired of using messy CAD spray to capture your abutment designs? If you have answered yes to either of these questions then don't need to worry, 3Shape’s “Split File Design” feature will solve all your problems.

Split File Designing

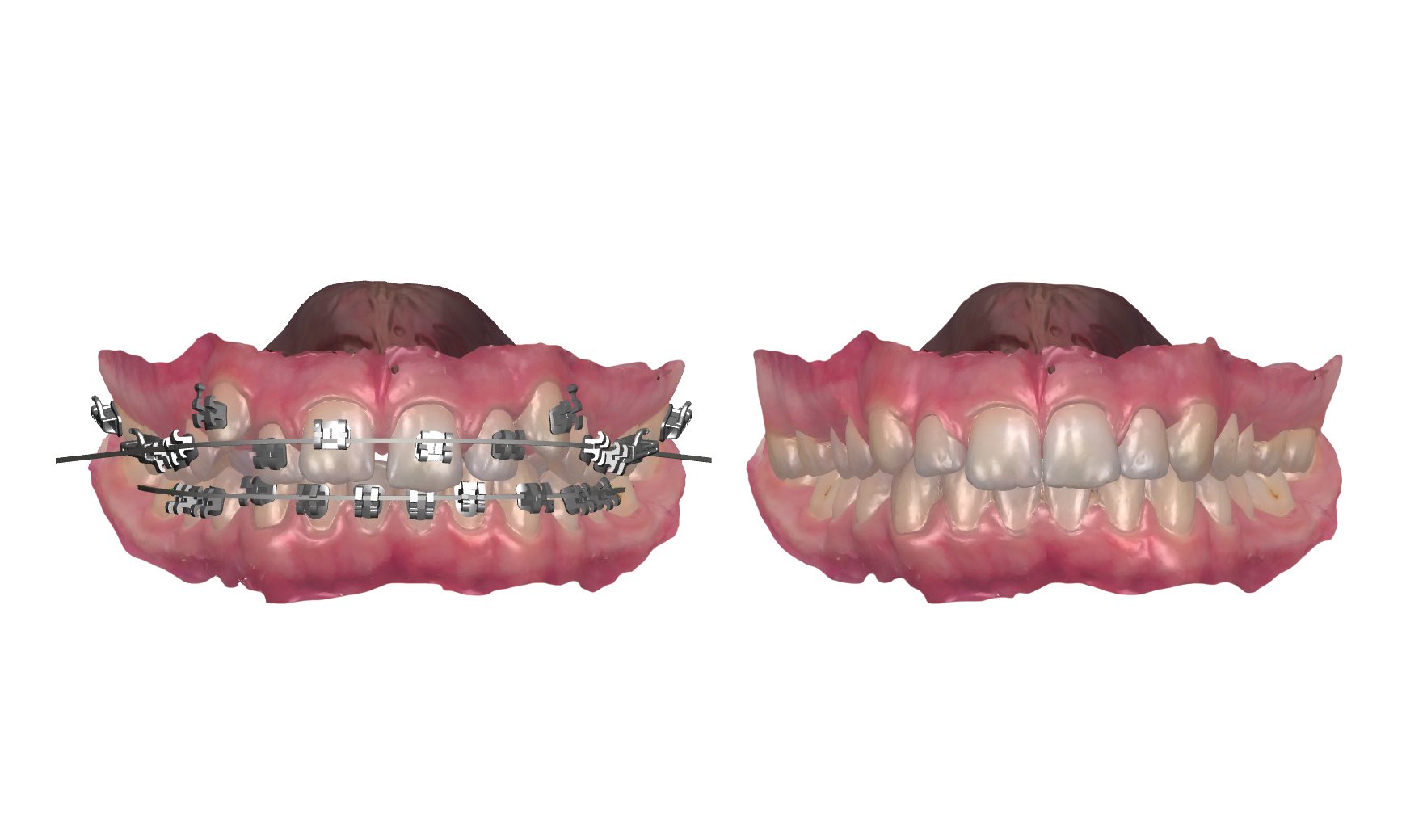

With split file designing you will be able to design your custom abutment and overlaying crown all in one design session. This introduces a number of benefits into the traditional workflow. In a traditional workflow you would first place scan bodies in the implant analogs and scan the model. Next, you would design the custom abutment and send it out to your titanium milling center. Once you received the milled abutment you would then spray it, place it back on the model and perform another scan. Finally, you would design the crown that will go on top. One of the major issues that I have had reported to me is the inaccuracy of fit between abutment and crown. This would make sense because the use of CAD scanning spray adds a variable of inaccuracy to the workflow. CAD sprays can be technique sensitive in their application. A light dusting is all that is needed to effectively scan, but how thick is a “light dusting?” Ten microns? Twenty microns? Fifty? There really isn’t a good way of measuring this spray layer; so most people rely on perception. We all know perception will vary between each technician that sprays the abutment.

The implementation of split file designing eliminates the need for CAD spray, thus eliminating the layer of inaccuracy. With split file designing you will first design a general tooth form for the indicated tooth. Next, you will design the custom abutment. The software will then allow you to specify exact values for your cement gap between the abutment and crown. Then you will make any final changes to your crown’s anatomy and the software will do the rest of the work splitting the two files apart. 3Shape also allows you to do several other time saving steps with split files. You can put a screw access hole through all the layers of your design and add screw hole protection if you’re putting a layered restoration on top.

Setting up an order for a split file workflow.

Setting up an order in 3Shape for a split file workflow is actually quite easy. In the order form select the teeth you need to restore. Next, select the type of custom abutment you want to create and select the necessary materials and manufacturers. Without unselecting the teeth, click the type of restoration you want to place over the abutment (i.e. Crown, Anatomic Coping) and pick the appropriate materials. That’s all you have to do! The scanning of the model will remain the same and the design flow will work as described above. Overall, I’ve found that split file designing has made my life a lot easier and a lot more accurate.

Leave a comment